EN-5

• See the installation manual accompanying indoor unit.

• Be sure to perform test run of indoor unit individually, and

then to perform all the units simultaneously.

• After the unit is turned off, the unit will not start operation for

3 minutes to protect the unit.

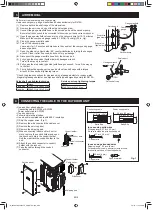

DSW1

OFF

1

2

ON

SW1

DSW1

SW2

PUMP DOWN

SELECT

WIRE CHECK

LED1A

LED1B

LED1C

LED1D

OFF

1

2

ON

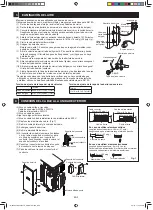

7 TEST RUN

8 ITEMS TO CHECK

Is the specifi ed power supply voltage used?

Is the connecting cable fi xed to terminal board fi rmly?

Is the earth wire connected properly arranged?

Is the drainage properly?

Is there any gas leakage at the pipe connection?

EXPLANATION TO CUSTOMER

• Explain to the customer how to use and maintain the system, referring to the

operation manual.

• Ask the customer to carefully read the operation manual.

• When the system has been set up, hand the installation manual to the

customer.

• During the heating operation, the unit will automatically stop when

the outdoor temperature drops below 5°F(-15°C) to prevent the

outdoor unit from the damage caused by the freezing of the drained

water. The unit will stop its operation for 4 hour and then resume the

operation when the outdoor temperature rises above 7°F(-13.9°C).

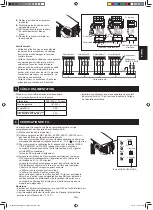

• To inactivate this function, slide the SELECT switch(DSW1) #1 to

OFF side.

SELECT switch (DSW1)

Lo

Hi

SW1

DSW1

SW2

PUMP DOWN

SELECT

WIRE CHECK

LED1A

LED1B

LED1C

LED1D

OFF

1

2

ON

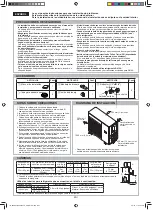

Pump down is adopted in the case of unit removal for re-installation, abandonment, repair etc.

Pump down is to collect the refrigerant into the outdoor unit.

PROCEDURE USING GAUGE MANIFOLD

(Recommended procedure)

(

1) Connect the gauge manifold hose to the service port of the stop valve(gas side).

(2) To start pump down, press the PUMP DOWN button(SW1) for 5 seconds or more.

The OPERATION lamp on the indoor unit will fl ash and three BEEP will be emitted.

(3) After 5-10 minutes, fully close the stop valve (liquid side).

(4) Close the stop valve (gas side) when the compound gauge reading becomes almost

0 MPa(0 cmHg).

(5) To stop the pump down, press the PUMP DOWN button(SW1) for 5 seconds or more.

(6) Disconnect the gauge manifold hose from the service port.

PROCEDURE WITHOUT USING GAUGE MANIFOLD

(1) To start pump down, press the PUMP DOWN button(SW1) for 5 seconds or more.

The OPERATION lamp on the indoor unit will fl ash and three BEEP will be

emitted.

(2) After 5-10 minutes, fully close the stop valve (liquid side) .

(3) After 2-3 minutes, close the stop valve (gas side) fully.

(4) To stop the pump down, press the PUMP DOWN button(SW1) for 5

seconds or more.

Caution:

• Make sure that the compressor is turned off before removing the refrigerant

pipes. Otherwise, it will cause burst and injury.

• Do not perform PUMP DOWN when refrigerant is leaking or there is no refrigerant in

the refrigerant cycle. Otherwise, it will cause burst and injury.

• In order to prevent malfunctioning of compressor, be sure to turn off the pump down

operation within 20 minutes after closing the stop valve of liquid side.

Note:

• Wait more than 90 seconds after fi nishing pump down, and turn off the

circuit breaker off.

Stop valve

(gas side)

Stop valve

(liquid side)

PUMP DOWN

PUMP DOWN button (SW1)

Gauge manifold

Compound

gauge

Service port

Note:

• Make sure not to slide the SELECT switch(DSW1) #2 to OFF side.

5°F(-15°C) AUTO STOP FUNCTION

IM_A3AEX4M3PU(B434)_EN+FR+ES.indb EN-5

IM_A3AEX4M3PU(B434)_EN+FR+ES.indb EN-5

2/7/13 11:05:31 AM

2/7/13 11:05:31 AM