EN-1

A

B

D

C

Trap

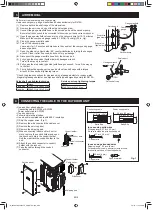

PIPING

Max. piping

length:A

Max. total piping length of all

unit

Min. piping

length:A

Max. height difference:

Chargeless Max.

piping length

Additional refrigerant

B

C

D

82 ft (25 m)

2 units:164 ft (50 m)

3 units, 4 units: 230 ft (70 m)

10 ft (3 m)

49 ft

(15 m)

49 ft

(15 m)

49 ft

(15 m)

164 ft (50 m)

0.16 oz/ft (15 g/m)

1. Standard piping length is 25 ft (7.6 m).

2. When the outdoor unit is placed at a higher level than the indoor unit, provide a trap near the hose’s lead-in port.

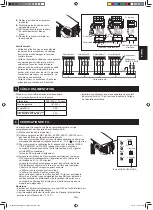

Use the refrigerant pipes shown in the table below.

Pipe size

Pipe thickness

Thermal insulation

Liquid side

1/4" (ø 6.35 mm)

0.03 inch (0.8 mm)

Thickness: 0.24 inch (6 mm) or thicker

Material: Polyethylene foam

Gas side

3/8" (ø 9.52 mm)

1/2" (ø 12.7 mm)

• The thermal insulation should cover both the gas and liquid pipes.

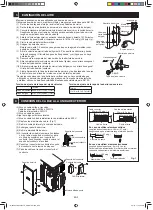

ACCESSORIES

ITEMS

Q’ty

ITEMS

Q’ty

ITEMS

Q’ty

1

Installation Manual

1

3

Drain tray

1

5

Reducer (1/2"

3/8")

2

2

Base pan cap

4

4

Drain joint

1

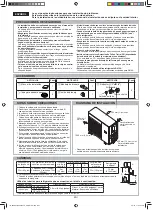

INSTALLATION DIAGRAM

3.3 ft (1000

mm) or more

1.3 ft (400

mm) or more

• Provide as much installation space as possible for

effi cient air-conditioning.

For installation work

1. Place the outdoor unit on a stable base.

2. Provided suffi cient space around the unit. It should also be

well ventilated.

3. The unit should not be exposed to strong wind nor splashed

with rain water.

4. Water drain from the unit should be let out without problem.

Lay a drain hose if required. In cold regions, installation of

the drain pipe is not advisable as freezing could result.

5. Keep TV sets, Radio and other related electronic appliances

at least 3.3 feet away from the unit.

6. Avoid locations exposed to machine oil vapor, salty air (facing

the seashore, for example), hot spring vapor sulfur gas, etc.

Such location can cause breakdown.

7. Avoid locations exposed to muddy water (along a road, for

example) or where the unit can be tampered with.

8. Select a location where the outgoing air or operating noise

cannot annoy others.

9. Keep the air outlet opening free of any obstacle. This could

affect the performance of the unit and create loud noises.

10.For colder climate areas, install the unit in a location not

affected by snow or ice falls (example: roof houses). Unit

should be installed minimum 10 inches (25 cm) from ground

level or follow your country’s average snowfall accumulation.

Carefully read and follow these instructions for smooth and trouble-free installation.

This manual describes the installation of outdoor unit only

For the installation of the indoor unit, see the installation manual accompanying indoor unit.

SAFETY PRECAUTIONS

• Tighten the fl are nut with a torque wrench according to the

specifi ed method.

If the fl are nut is tightened too hard, the fl are nut may be broken after a

long time and cause refrigerant gas leakage.

• When installing the unit, take care not to enter air substance other

than the specifi ed refrigerant(R410A) in the refrigerant cycle.

Otherwise, it will cause burst and injury as a result of abnormal high

pressure in the refrigerant cycle.

• Be sure to connect the refrigerant pipe before running the

compressor.

Otherwise, it will cause burst and injury as a result of abnormal high

pressure in the refrigerant cycle.

• Ground the unit.

Incomplete ground may cause electrical shock.

• Install a Ground Fault Interrupt (GFI) circuit breaker depending on

the installation location of the unit (such as highly humid areas).

If GFI breaker is not installed, it may cause electric shock.

• Arrange the drain hose to ensure smooth drainage.

Insuffi cient drainage may cause wetting of the room, furniture etc.

• This room air conditioner uses refrigerant R410A.

Use the pipe, fl are nut and tools exclusively for R410A.

NOTES ON LOCATIONS

1 ft (300

mm)

or more

• Installation must be made in accordance with the installation

manual by qualifi ed service personnel.

Incorrect work will cause electric shock, water leak, fi re.

• Be sure to use the attached accessories parts and specifi ed

parts for installation.

Use of other parts will cause electric shock, water leak, fi re, the unit

falling.

• The appliance shall be installed and wired in accordance with

National Electrical Code and by qualifi ed personnel only.

Wrong connection can cause overheating or fi re.

• After installation has complete, check that there is no leakage

of refrigerant gas.

If the refrigerant gas contact with fi re, it may generate toxic gas.

• Ventilate the room if refrigerant gas leaks during installation.

If the refrigerant gas contact with fi re, it may generate toxic gas.

• Use the specifi ed electrical cable.

Make sure the cable is secured in place and that the terminals are

free of any excess force from the cable. Otherwise overheating or

fi re may result.

• Form the cable so that the control box cover, the cord holder

and cable holder are not loose.

Otherwise overheating, fi re or electric shock may result.

Coating tape

(Commercially available)

Joint

Seal Ring

Flare nut

ENGLISH

1 ft (300

mm) or more

IM_A3AEX4M3PU(B434)_EN+FR+ES.indb EN-1

IM_A3AEX4M3PU(B434)_EN+FR+ES.indb EN-1

2/7/13 11:05:27 AM

2/7/13 11:05:27 AM