BK-T080III (vertical) User’s Manual

- 34 -

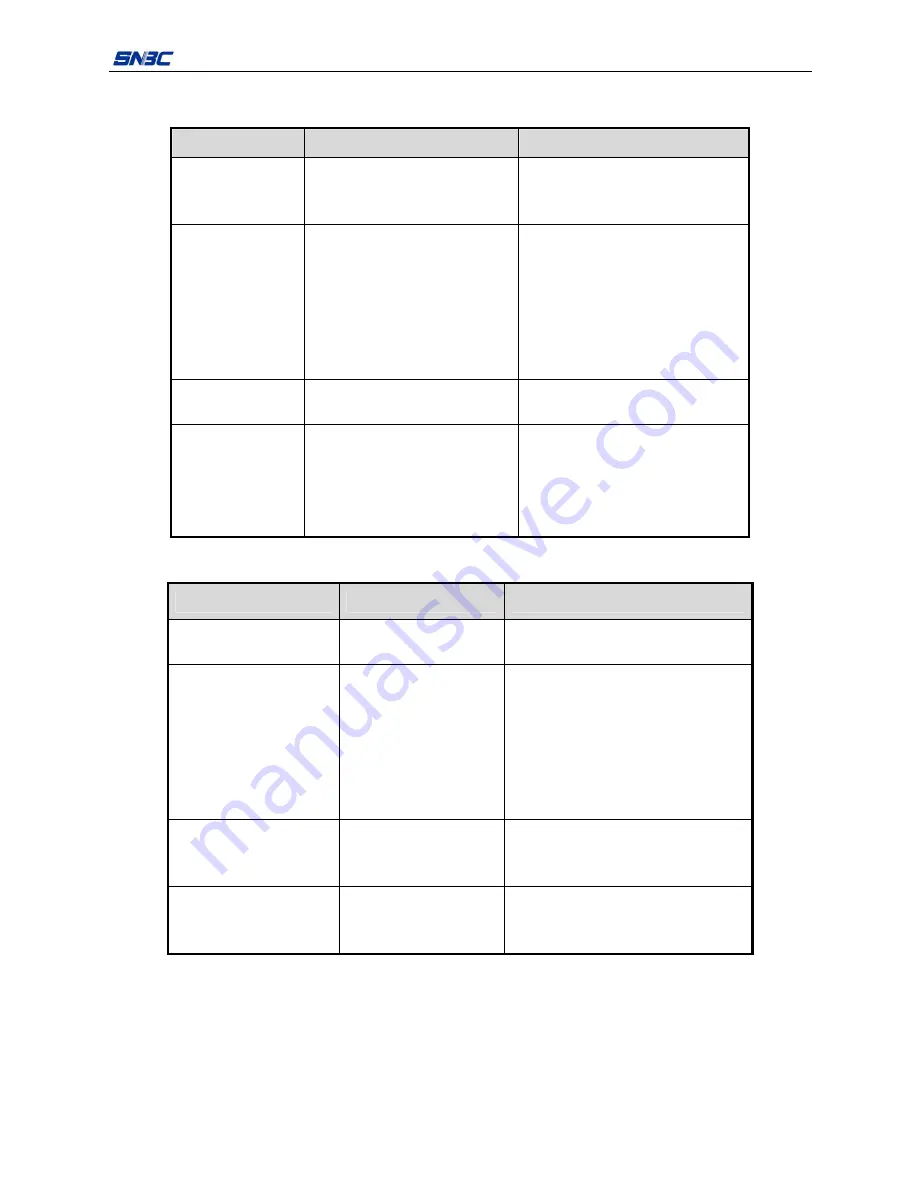

7.2 Solution for common errors

7.2.1 Problems during paper loading

Problem

Possible reasons

Solutions

Paper roll can’t be

loaded onto paper

holder smoothly

The paper roll ID does not match

the printer

Replace paper roll.

The printer can’t

feed paper

automatically

Paper head is irregular;

Paper jams;

The paper loading sensor is not

covered by paper head;

Dust and wastepaper covers the

paper loading sensor.

Trim the paper head according to

requirements;

Remove jammed paper;

Check the paper head to confirm that

the paper loading sensor is covered

fully by paper;

Clean the paper loading sensor.

The buzzer alarms

Paper end;

The platen roller is not closed.

Replace the paper roll;

Close the platen roller.

After automatic

paper feeding, the

paper can’t stop in

the normal print

position

Dust or wastepaper covers the

paper loading sensor.

Clean the paper loading sensor.

Table 7.2-1 Errors during paper loading

7.2.2 Problems during printing

Problems

Possible reasons

Solutions

The receipt can’t be ejected

out smoothly.

Paper jams.

Check paper feeding path, remove

wastepaper and reload paper.

Printout is not clear.

The paper is loaded in

wrong direction or its

quality is poor;

Print head needs cleaning;

The print darkness is too

low;

Input voltage is too low.

Load the paper roll correctly;

Use recommended paper or its

equivalents;

Clean the print head;

Adjust print darkness (

*

);

Use the power supply which meets

requirements.

Cutter works abnormally.

Paper jams in cutter;

The cutter is broken.

Check if there are sundries in cutter

path(

*

), contact with SNBC or your local

distributor.

Printing data is lost and no

printing.

The platen roller is not

closed;

Paper jams.

Close the platen roller properly;

Remove jammed paper.

Table 7.2-2 Problems during printing

*

To adjust print darkness, contact with our distributors or SNBC.

*

If paper jams in cutter, please remove the jammed paper firstly, and then press CUT button to reset the

cutter.