BREEZAIR EXQ/EZQ/EXS EVAPORATIVE COOLERS INSTALLATION MANUAL

|

9

Installation of the cooler must conform to local electrical rules,

regulations and standards.

Important!

It is a requirement of Seeley International that

all Breezair coolers be connected to a dedicated circuit to

the distribution board, with a separate circuit breaker and

incorporate all pole disconnection switch in accordance with the

local wiring rules.

A 10A socket outlet within one metre of the dropper’s cable exit

hole is required.

The following specifications for the cooler electrical supply are

required:

220V, 220-240V, 230V, 240V / 50Hz, 60Hz Single Phase

WARNING!

If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or a similarly qualified

person in order to avoid a hazard.

ELECTRICAL REQUIREMENTS

Installation of the cooler water supply must conform to

local plumbing rules, regulations and standards.

The following specifications for the cooler water

supply are required:

Water Connection

½

”

BSP

Min Water Pressure

100kPa (15psi)

Max Water Pressure

800kPa (115psi)

Min Water Flow

8 liters/min (2.1 gallons/min)

Max Water Temperature

40°C (104°F)

Important!

If the water pressure exceeds maximum

specification then a pressure reducing valve is required

and must be supplied and fitted by the installer.

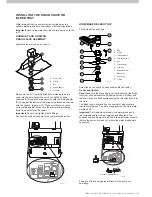

Harmony & Horizon

For coolers with the inlet solenoid valve fitted, the water

connection is a 1/2” BSP compression fitting on the end of a

flexible hose. This can fit directly onto the water pipe or be

screwed directly onto the manual water shut-off valve. Always

ensure that the water pipe connection does not place sideways

strain onto the float valve.

Homemaker

A permanent water supply is required to be connected to the float

valve. The water connection point is located on the underside

of the cooler. The water connection fitting is a 1/2” BSP male

adaptor suitable for a compression fitting. Do not fit the manual

water shut-off valve directly onto the plastic nipple. You must

install a manual 1/4 turn ball type shut off valve (do not use a

stop cock) in the water supply line adjacent to the cooler, subject

to local plumbing regulations. This allows the water supply to be

isolated whenever work needs to be done on the cooler.

Important!

In areas subject to freezing, the water supply line

to the cooler requires a drain down facility at the lowest point in

the water supply pipe.

Important!

Flush the water pipe to remove any swarf before

final fitting. Swarf can lodge in the solenoid and float valve,

preventing them from functioning correctly.

WATER REQUIREMENTS

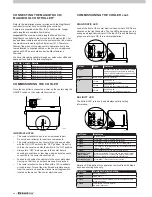

MULTIPLE COOLER INSTALLATIONS WITH

EXTERNAL AIR SENSOR

Ensure all cooler electronics dipswitches are set to ‘OFF’ except

for the last cooler in series. The last cooler dipswitch should be

switched to ‘ON’ to ensure communication reliability.

Only 1 x External Air Sensor will operate in a multi-cooler

installation. If multiple External Air Sensors are fitted disconnect

the External Air Sensor plug from each of the cooler electronics’

except for the last cooler in the series.

UP TO 135

COOLERS OR

1X EXTERNAL

AIR SENSOR

ILL2194-A

EXT

EXT

Cooler electronics fitted with External Air Sensors or have a

spare RJ connector can be installed as follows;