5

SI1000

Operator Guide (SV62138 Rev. A)

Your new SI1000 is a compact folding and inserting machine de-

signed to speed the process of mail creation.

It has a minimal number of user adjustments and an intuitive, easy-

to-use control panel. This greatly simplifi es machine operation and

will enhance the productivity of your mailing operation.

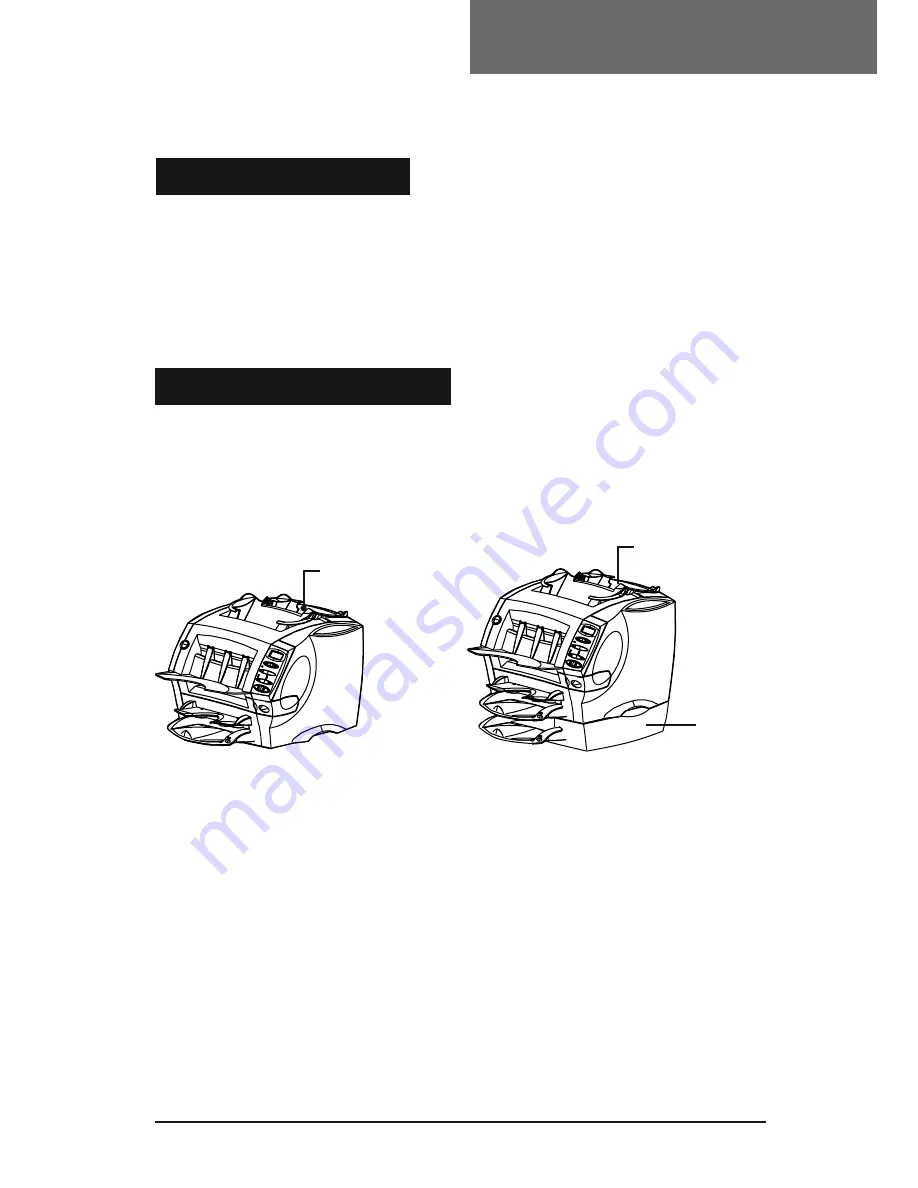

There are two confi gurations of the SI1000 available. The basic

model is supplied with an insert feeder and one sheet feeder. The

second confi guration is supplied with an insert feeder and two sheet

feeders.

Introduction

Machine Confi gurations

About Your Machine

Confi guration 1

Basic machine with insert

feeder and one sheet feeder

insert feeder

Confi guration 2

Machine with insert feeder

and a 2nd sheet feeder added

2nd sheet

feeder

insert feeder