16

Vario M

Problem

Possible cause

Solution

Workpiece is excentrically out

of tolerance

Segmented mandrel run-out error

Check and, if necessary readjust,

run-out of the mandrel outer taper

Insufficient clamping force

Workpiece is oversize

Too low tightening torque

Swap in suitable segmented clamping

sleeve

Check the set torque

Workpiece is out of tolerance

Dirt between segmented clamping

sleeve and mandrel taper.

Remove and clean the screw and

segmented clamping sleeve

Workpiece bent out of shape

A workpiece initially bent out of shape is

deformed during the clamping process.

After machining, it should go back to

its original shape

Use material that is less bent out of

shape initially

Marks on the clamping area

Point or linear workpiece clamping

The difference between the clamping

diameter and the workpiece bore is too

large. Change to a segmented clamping

sleeve that fits

Axial run-out error on the

workpiece

Dirt on the mounting surfaces

Clean the soiled surfaces

Workpiece is not clamped

Clamping bolt has not been fully tightened

Dirt between mandrel body and

ejector ring

The rotating carriers of the ejector ring

do not engage with the slots

Fully tighten clamping bolt

Clean the mandrel body and of

the ejector ring

Reposition segmented clamping sleeve

8.

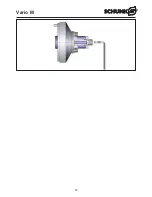

Ausführungen und Ersatzteile

8.

Types and spare parts

Bei Bestellung von Ersatzteilen ist es unumgänglich,

die Type, Größe und vor allem die Fertigungs-Nr. des

Futters anzugeben, um Fehllieferungen zu vermeiden.

Grundsätzlich sind Dichtungen, Dichtelemente,

Verschraubungen, Federn, Lager, Schrauben und

Abstreiferleisten sowie werkstückberührende Teile

nicht Bestandteil der Gewährleistung.

When ordering spare parts, it is necessary to indicate

the Type, and, most importantly, the manufacturing

number of the chuck to avoid wrong deliveries.

The warranty in general does not cover seals, seal-

ing elements, screw connections, springs, bear-

ings, screws and wipers as well as components

which come into contact with the workpiece.

Dorngröße /

Mandrel size

Futter / Chuck

Ident-Nr. / Id.-no.

M0

ROTA-S vario 200

8704867

ROTA-S vario 250

8704868

M1

ROTA-S vario 200

8704871

ROTA-S vario 250

8704872

M2

ROTA-S vario 200

8704875

ROTA-S vario 250

8704876

M3

ROTA-S vario 250

8704878

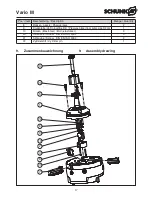

Pos. / Item

Beschreibung / Description

Menge / Quantity

1

Grundkörper / Base body

1

2

Kolben / Piston

1

3

Schraube / Screw

1

4

Deckel / Cover

1

5

Ring / Ring

1

6

Bolzen / Bolt

3

7

Backe, aktiv / Active jaw

1

Summary of Contents for Vario M

Page 22: ...22 Vario M ...