Maintenance

58

06.00 | NSR-A | Assembly and Operating Manual | en | 389722

7.2 Information on error-free function

To ensure the pallet changing system operates perfectly, the

following instructions are to be observed:

• Pressure medium: compressed air - Observe the requirements

for the compressed air supply, ,

• Make sure that the contact surfaces of the interface are always

clean.

• Always ensure that no chips enter the interface.

• Only use high-quality cooling emulsions with anti-corrosive

additives during processing.

• Particularly with the clamping pin axis aligned vertically, it may

be possible that the interface fills up with cooling emulsion. If

this is the case, initiate the unlocking process and dry out the

interface in actuated state.

• Check the pallet changing system at regular intervals. The

system is functioning correctly if the clamping slides move

smoothly at minimum system pressure (5 bar).

7.3 Carry out visual inspection and check for leaks

Visual inspection

• Inspect the pallet changing system for possible damage and

wear.

• After a collision, e.g. when connecting or disconnecting the

transport load, carry out a visual inspection for possible damage

to the components, e.g. cracks.

• If damage or signs of malfunctions are identifiable on the pallet

changing system, it may not be restarted. They can only be

started up again once the faults have been remedied, for

example, by replacement of the damaged components.

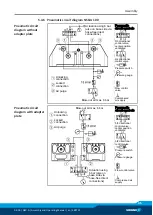

Leak test

• Test the pallet changing system for leaks in both module

positions (unlocked and locked).

• To identify any leaks in the complete clamping system, no pallet

adapter should be fitted.

• If the clamping system has leaks, check the entire pneumatic

system (e.g. using Metaflux leak detector spray).

• If any leaks are identified, check the seals and replace them if

necessary.

Leaks at the plug-in connections or in the pneumatic lines, for

example, must be sealed and defective components replaced.