1. Handle

2. Table

3. Drawer

4. Front cover

5. START button

6. Touch display

7. Indicator lamp

8. Side cover

9. ON/OFF switch

10. Pumps

11

. Nozzles

12.

Valve tank 1 / tank 2

13. Valve water / pretreatment

14. Upper cover

15. Main switch

16. Power cord with plug

17. Waste tank cable connection

18. Stand (optional)

19. Deposit tank

20. Deposit tank base with sensor

21. Outlet

Version 22.01

1.

4

Technical data

Weight

Spraying area

Dimensions of the machine

Dimensions of the machine for transport

Technical data

Weight for transport

Power supply voltage

Power consumption

Number of nozzles

Main fuse

Nozzle pressure

Noise

Rated power

Length of drawer

1

,6

A

76

kg

80 cm

7

3

x 9

8

x

52

cm

m

a

x

.

5

,0 bar

The machine generates noise less than 70 dB (A)

6 A

97

kg

4

2

x 60 cm

1

6

0 W

80 x 95 x 61 cm

5

pcs

PRETREATmaker

5

1

0

0 - 240 VAC

98

x

103

x

70

cm

1

0

0 - 240 VAC

91 kg

1

,6

A

98

x

96

x

52

cm

1

6

0 W

m

a

x

.

5

,0 bar

80 cm

5 pcs

PRETREATmaker 5 MAX

6 A

114 kg

63

x

63

cm

The

PRETREATmaker 5

(MAX)

is destined for automatic

pretreatment

application for

DTG

printers.

The textile should be placed on the drawer

and after closing the drawer and pressing the START button, the pretreatment is applied. The pretreatment is applied directly over the textile. The

tanks may only be filled with the pretreatment fluid approved by the manufacturer. The amount of pretreatment applied can be adjusted by

adjusting the speed, single or double spray setting, pump pressure and calibration. The machine settings can be adjusted individually for material

or job, the following technique can be used for this purpose:

- Barcode scanner

1

.

5

Use and example of settings

21

Main fuse

6A

12

/ 24

V

AC

Instal

lation

All control elements of the machine are supplied with a safe voltage, not higher than 24V. Voltage of 100-240 VAC is present in the back part of the

machine only.

The P

RETREATmaker 5

(MAX)

is equipped with different safety arrangements, to make a safe usage possible.

The main fuse

(6A)

is located on the back side of the machine. In case of overload it protects the device against damage. If the fuse was activated it

has to be replaced. Instructions for replacement of the fuse can be found in chapter 4.7

20

19

18

17

16

15

21

E

N

G

L

IS

H

1.6

Safety arrangements of the machine

1.7

Safety arrangements at the workplace

Set-up and installation

The set-up and installation of the machine has to be done under supervision of an authorized person.

Due to the weight of the device, its

installation must be done by two or more people according to the instructions given in this manual. The machine should be situated on the flat

surface, in a room with constant temperature and moisture. Keep the machine away from dusty rooms, because dust could have a negative

influence on some parts of the machine. Very important! The machine may be connected only to an installation equipped with a protection against

electric shock. The machine is destined for industrial use only.

Summary of Contents for PRETREATmaker 5

Page 2: ......

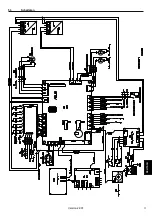

Page 17: ...5 3 Schaltplan Version 22 01 17 DEUTSCH ...

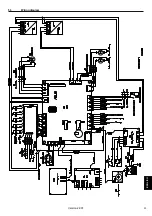

Page 33: ...5 3 Wiring diagram Version 22 01 ENGLISH 33 ...

Page 49: ...5 3 Schemat połączeń 49 POLSKI Wersja 22 01 ...

Page 51: ......

Page 52: ......