UNM

II/3

GB

direction. The screw it open by 1/2 to 1

turn (Figure 3a).

2. During air extraction, oil deposits in the

form of droplets can be seen at the upper

sight glass. Dosing: 1 droplet oil at 300

– 600 l/min air consumption. Readjust If

necessary and check regularly.

2.5 Operation

L

Do not overload the compressor: do not

exceed the max. number of switching cy-

cles and the ratio of operating time to

standstill!

2.5.1 Insert

Switch on the compressor at the ON/OFF

switch (item 10). The compressor starts up

and switches off automatically at maximum

pressure.

2.5.2 Adjusting the working pressure

1. Pull up the adjustment button on the (fil-

ter) pressure reducer (Figure 4a).

2. Rotate clockwise = pressure is in-

creased. Rotate anticlockwise = pressure

is reduced.

3. Read the set working pressure on the

pressure gauge (item 13).

4. Press the adjustment button down to

lock it in place.

2.5.3 After use

1. Switch off the compressor.

2. Disconnect the power supply.

3. Disconnect plug nipple of air hose from

(safety) quick-action coupling (Fig. 3a) .

4. Clean compressor (Chap. 2.6.2), depres-

surise it (Chap. 2.6.1), transport to stor-

age location (Chap. 2.4.1).

2.6 Maintenance

2.6.1 Before each maintenance task

1. Swtich on the compressor at the ON/OFF

switch (item 10). Disconnect the power

supply.

2. Depressurise the compressor: using the

blow gun, blow out all pressure from the

vessel.

L

Only drain oil if the unit has been suffi-

ciently cooled.

2.6.2 Cleaning the compressor

• Clean the cooling fins on the cylinder, cyl-

inder head and aftercooler using com-

pressed air.

• Clean the fan impeller cover on the motor.

2.6.3 Clean FDM insert

1. Depressurise vessel of FDM.

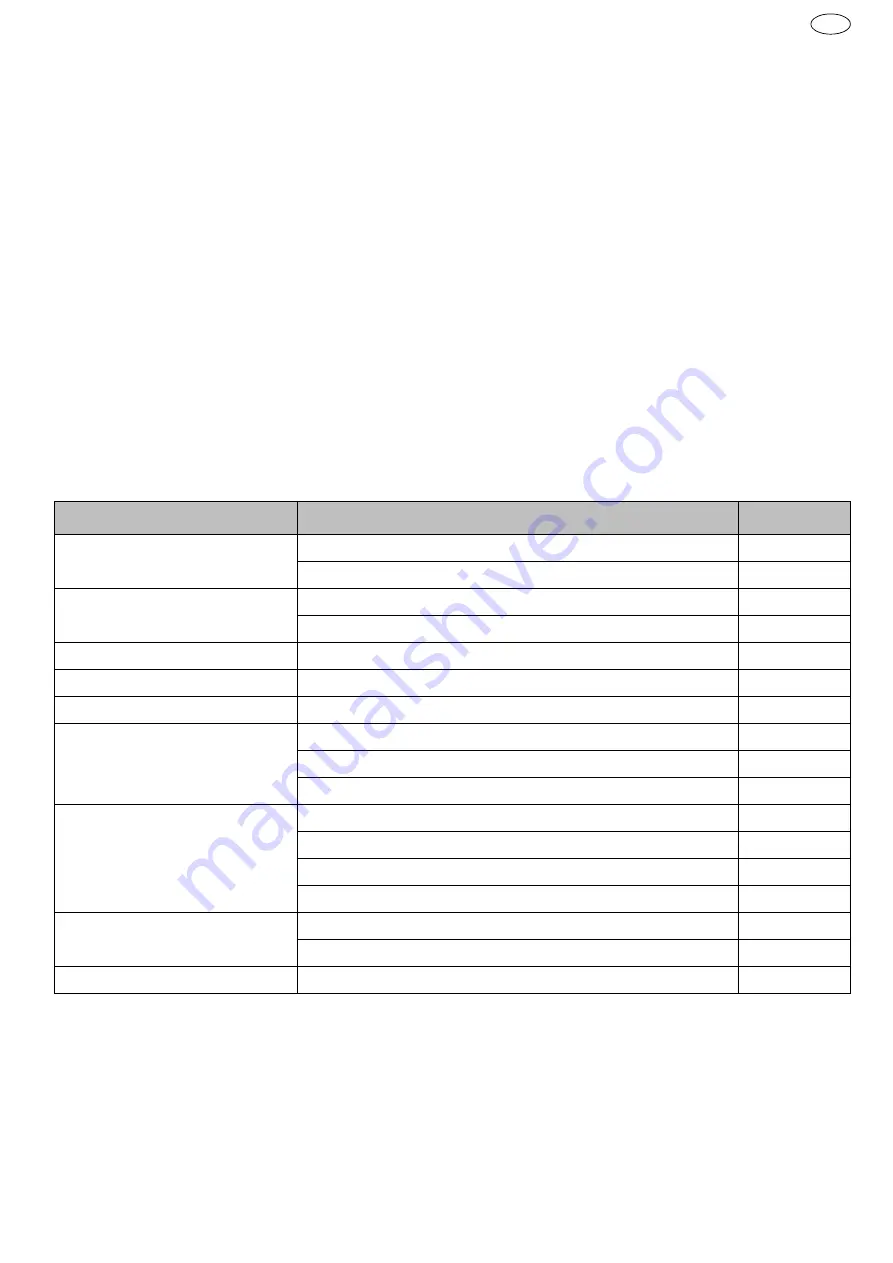

Interval / No later than Tasks

See chap.

-- / As needed

Clean compressor

2.6.2

Clean filter insert (FDM)

2.6.3

-- / after each use

Drain condensate from pressure vessel

2.6.5

Drain condensate from FDM

2.6.4

daily / commissioning

Check the oil level, add oil if necessary.

2.6.6

Once after 10 h / --

Check screw connections

2.6.8

-- / Weekly

Check intake filter

2.6.9

50 h / After 6 months

Check V-belt tension (where applicable)

2.6.10

Clean intake filter

2.6.9

Change oil (1st oil change mineral or synthetic oil) 2.6.7

500 h / after 1 year

Change oil (with mineral oil)

2.6.7

Change intake filter

2.6.9

Change check valve and insert

2.6.11

Check screw connections

2.6.8

1,000 h / after 2 years

Change oil (with synthetic oil)

2.6.7

Change V-belts (where applicable)

2.6.10

2,500 h / After 5 years

Change safety valve

2.6.12

Summary of Contents for A 713 010

Page 3: ...5a 8a 2a 6a 7a 4a 8b...

Page 79: ...UNM II 63 RUS 2 3 Schneider Druckluft GmbH 38 2 4 2 4 1 2 4 2 2 4 3 1 2 3 2 6 6 L X X X X X X...

Page 84: ...II 68 UNM RUS C X X A X D X 2 4 4 E X X X X 2 6 5 X X F X G X 2 6 11 X H X 2 6 5 X E...

Page 85: ...UNM II 69 RUS 2 9 I X X J X X X K X X L X X 2 6 10...