31

LAWNAIRE ZTS

CHAIN REPLACEMENT

NOTE:

It is recommended replacement chains

from Schiller Grounds care, Inc. be used. Schiller

Grounds Care, Inc. supplies a premium quality chain

cut to the correct length. Replace all chains together

for best results under normal circumstances.

Tension on new chains will need to be adjusted after

the first several hours of operation after the chains

run in. See Chain Adjustment Section.

MAIN DRIVE CHAIN

1. Start the engine and raise the machine on the

jack stands. See jack stands section page 19.

Stop the engine. Open the transaxle by pass

valves so you can rotate the tines and axles

manually.

2. Remove the front, side and tine chain covers.

3.

Pull the tensioner forward while lifting on the

end opposite of the spring to lock it in place.

NOTE: If replacing all chains, leave main chain

broken and lying in place while the wheel and tine

chains are replaced. It is easier to replace those

chains with the main chain broken because the

wheel and tine sprockets turn freely with the main

chain disconnected.

4. Break the chain by removing the connector link.

Inspect the sprockets. If any sprockets are worn,

remove the chain and replace sprockets before

installing the new chain. If the sprockets are still

in good condition, connect the new chain to the

old chain and use the old chain to pull the new

chain around the sprockets. Remove the old

chain and connect the ends of the new chain

with a new connector link. NOTE: Install all con-

nector links so the closed end is in the direction

of forward travel.

5. Push the idler up to take all the slack out of the

new chain and tighten the idler bolt. Make sure

the slack is out of the top span of the chain.

Move the tensioner off the locking notch to en-

gage the locking teeth.

6. Reinstall the chain covers. Start the engine and

lower the machine. Stop the engine and pin the

jack stands in the operating position.

TINE CHAIN

Tines may drop suddenly. Support tines when work-

ing underneath them.

1. Start the engine and raise the machine on

the jack stands. Stop the engine. Open the

transaxle by pass valves so you can rotate the

tines and axles manually.

2. Remove the front, side and tine chain covers.

3. Break the main chain and leave it lying on the

machine.

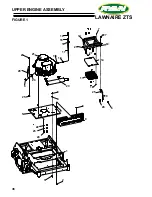

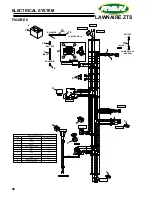

Figure 1

4. Loosen the idler mounting bolt and back off the

idler.

5. Break the chain by removing the connector link.

Inspect the sprockets. If any sprockets are worn,

remove the chain and replace sprockets. If the

sprockets are still in good condition, connect

the new chain to the old chain and use the old

chain to pull the new chain around the sprockets.

Remove the old chain and connect the ends of

the new chain with a new connector link. NOTE:

Install all connector links so the closed end is in

the direction of forward travel.

6. Take the slack out of the chain by moving the

idler in the adjusting slots. Tighten the idler

mounting bolt. Reinstall main chain.

7. Reinstall the chain covers. Start the engine and

lower the machine. Stop the engine and pin the

jack stands in the operating position.

FIGURE 1