23

LAWNAIRE ZTS

MAINTENANCE

TRANSAXLE & HYDRAULIC OIL

Do not perform engine maintenance without the en-

gine off and spark plug wires disconnected.

- Check cold.

- Add 20w50 oil if necessary to the indicated level.

- Do not overfill. When the oil warms up it ex

-

pands. If overfilled cold, the oil may overflow at

operating temperature.

Change the transaxle / hydraulic lift circuit oil

after the first 75-100 hours, then every 200 hours

or yearly.

It is essential that the exterior of the transaxle be free

of debris, prior to fluid maintenance.

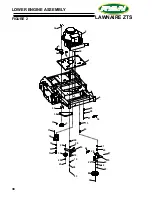

1. Raise the machine on the built in jack stands.

Remove the protective filter cover over the

hydraulic oil filter on each transaxle. Put an oil

drain pan under the transaxle hydraulic oil filters.

Remove the filters

A

. This will drain the oil from

the transaxles. With another drain pan, drain the

oil from the reservoir through the drain

D

on the

lower left side if the reservoir. Remove the lift

circuit filter. Dispose of the used oil and filters

properly.

2. Apply pipe compound to the reservoir drain plug

and reinstall in the reservoir. Oil the gaskets of

the new transaxle hydraulic oil filters and install

on the transaxles. Tighten 3/4 to 1 turn past

the point where the gasket contacts the mount-

ing surface. Reinstall the filter covers. Oil the

gasket on ta new lift circuit filter and install on the

filter head. Tighten 3/4 to 1 turn past the point

where the gasket contacts the filter head. NOTE:

The transaxle filters are smaller then the lift cir

-

cuit filter.

3. Fill the reservoir with 20w50 (15w50 is accept-

able) motor oil to the top. (Approximately 4 qts.).

4. Have more oil ready. Open the transaxle bypass

valves. Keep the machine transaxle controls in

neutral. Crack the lift pump outlet fitting, start

the machine. Place some rags under the fitting.

When oil appears, tighten the fitting. The lift

circuit pump will fill the transaxles. Add oil as

the level drops below the "FULL COLD" mark.

Run the machine and keep adding oil until the oil

level stabilizes. If the controls were not moved

out of neutral, purging should not be required.

Drive the machine and check oil level. Top off as

necessary.

5. If the transaxles are noisy or jerky, purge the

transaxles, following the purging procedures.

See

Purging Transaxles Page 9

.