www.scheppach.com /

+(49)-08223-4002-99 /

+(49)-08223-4002-58

GB | 31

Please provide the following information in the event

of any enquiries:

• Type of current for the motor

• Machine data - type plate

• Machine data - type plate

11. Cleaning, maintenance, storage

and ordering spare parts

m

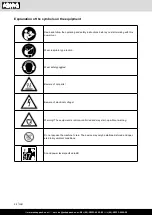

Important!

Pull out the power plug before doing any cleaning

and maintenance work on the equipment. Risk of

injury from electric shock!

m

Important!

Wait until the equipment has cooled down complete-

ly! Risk of burns!

m

Important!

Always depressurize the equipment before carrying

out any cleaning and maintenance work! Risk of in-

jury!

11.1 Cleaning

• Keep protective devices, air vents and the motor

housing as free of dust and dirt as possible.

• We recommend that you clean the device directly

after every use.

•

Rub the device clean with a clean cloth or blow it off

with compressed air at low pressure.

• Clean the device at regular intervals using a damp

cloth and a little soft soap. Do not use any cleaning

products or solvents; they could attack the plastic

parts of the device. Make sure that no water can

penetrate the device interior.

• The hose and injection tools must be disconnected

from the compressor before cleaning. The com-

pressor must not be cleaned with water, solvents

or similar.

11.2 Maintenance work on the pressure vessel

(fig. 4)

m

Important! To ensure a long service life of the

pressure vessel (7), drain off the condensed wa

-

ter by opening the drain valve (11) each time af-

ter using.

Release the vessel pressure at the overpressure

valve (2) beforehand. Open the drain screw by turn-

ing counter-clockwise (looking at the screw from the

bottom of the compressor) so that all the condensed

water can run out of the pressure vessel. Then close

the drain screw again (turn it clockwise). Check the

pressure vessel for signs of rust and damage each

time before using. Do not use the compressor with

a damaged or rusty pressure vessel. If you discover

any damage, then please contact the customer ser-

vice workshop.

m

Important!

The condensed water from the pressure vessel will

contain residual oil. Dispose of the condensed water

in an environmentally compatible manner at a suit-

able collection point.

11.3 Safety valve (Fig. 1)

The safety valve (5) has been set for the highest per-

mitted pressure of the pressure vessel. It is not permit-

ted to adjust the safety valve or remove the connec-

tion lock (5.2) between the exhaust nut (5.1) and its

cap (5.3).

Actuate the safety valve every 30 operating hours but

at least 3 times a year, to ensure that it works when

required. Turn the perforated exhaust nut (5.1) coun-

terclockwise to open it and use your hands to pull the

valve rod outwards over the perforated exhaust nut

(5.1) to open the safety valve outlet. Now, the valve

audibly releases air. Then, tighten the exhaust nut

clockwise again.

11.4 Storage

Store the device and its accessories in a dark, dry

and frost-free place that is inaccessible to children.

The optimum storage temperature lies between 5 and

30 ˚C.

m

Important!

Pull out the mains plug and ventilate the equip-

ment and all connected pneumatic tools. Switch

off the compressor and make sure that it is se

-

cured in such a way that it cannot be started up

again by any unauthorized person.

m

Important!

Store the compressor only in a dry location

which is not accessible to unauthorized per-

sons. Always store upright, never tilted!

11.5 Transport

• Use the transport handle (1) to transport the device,

and drive the compressor with it.

• When lifting the compressor, note its weight (see

technical data).

• Ensure that the load is well secured when trans-

porting the compressor in a motor vehicle.

11.6 Ordering spare parts

Please provide the following information when order-

ing replacement parts:

• Device type

• Device article number

• Device ID number

• Replacement part number of the required replace-

ment part