Smoke extraction damper ERK-SO

TECHNICAL DOCUMENTATION

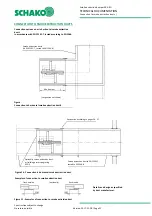

Installation details |

Construction subject to change

No

return

possible

Version:

2017-11-28

|

Page

9

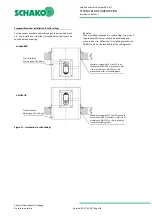

Please note

If H

≤

400 mm, the housing must be extended for this arrangement. If the wall thickness is > 100 mm, always check

whether the housing needs to be extended on the b side (MS) - see page 6 Table 2 - (the available wall thickness and a

possible connection to the smoke extraction duct must be taken into account).

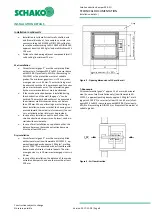

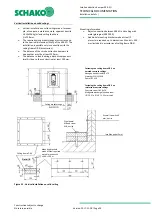

Wet installation

Dry installation

Detail A

Mortar of category M2.5 to M15 in accordance with EN

998-2 (previously: MG II to III according to DIN 1053) or

fire protection mortar of suitable grades. Gap

≥

10

≤

60

mm

* the dimensions of the threaded rods and the U-steel can be

found on pages 24 - 27.

Suspension *

Detail B

Mineral wool A1, melting point

≥

1000 °C / gap 15±5 mm

In the lower gap, place (only

in case of filling with mineral

wool) 2 spacers made of sili-

cate structural panel (di-

mens. W = 20 mm x L = 50

mm x H = gap height 10 – 20

mm) each approx. 50 mm

from the outer housing of

the ERK-SO.

Wall

Wall

Circumferential frame 40 x 40

made of silicate structural

panel at a distance of 150 mm

screwed to the ERK-SO hous-

ing with Spax screws 5 x 80

and glued with

water glass

glue

(SBK 2000).

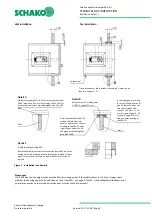

Detail C

Profile connection frame PAR

Installation example with profile connection frame PAR when con-

nected with a continuation smoke extraction duct made of sheet

metal for use within the fire area from which smoke is to be ex-

tracted.

Figure 5 - Installation in solid walls