Smoke extraction damper ERK-SO

TECHNICAL DOCUMENTATION

Installation details |

Construction subject to change

No

return

possible

Version:

2017-11-28

|

Page

11

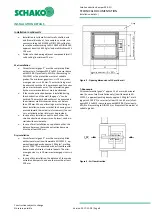

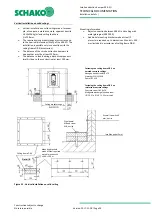

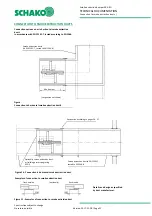

Please note

If H

≤

400 mm, the housing must be extended for this arrangement. If ERK-SO are arranged next to each other with horizontal

axis, the heads of hexagon screws must be countersunk. The ERK-SO must always be filled with mortar. If the wall thickness is >

100 mm, always check whether the housing needs to be extended on the b side (MS) - see page 6 Table 2 - (the available wall

thickness and a possible connection to the smoke extraction duct must be taken into account).

Mortar of category

M2.5 to M15 in ac-

cordance with EN

998-2 (previously: MG

II to III according to

DIN 1053) or fire pro-

tection mortar of suit-

able grades.

Gap

≥

10

≤

60 mm

U-steel

B vertical axle 1

5

0

0

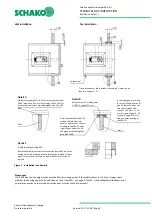

Mortar of category

M2.5 to M15 according to

EN 998-2 (previously: MG II to III ac-

cording to DIN 1053) or fire protec-

tion mortar of suitable grades.

Gap

≥

10

≤

60 mm

Connection of the two smoke

extraction dampers

(on site) with hexagon head

screws with shaft similar to

DIN 931 (ISO 4014)

M8 x 100 mm

U-washers according to DIN

125 (ISO 7089) int. Ø 8.4 /

out. Ø 16 / 1.6 mm thick

Drive-in nut M8 with

4 prongs (galvanized steel)

d2 = 22, d3 = 10, h = 15

SECTION A-A

DETAIL B

Insulfrax paper 5 mm thick (glued ex

works to the ERK-SO over the entire

surface with water glass glue.)

ERK-SO housing

Bores Ø 10 mm

Figure 7 - Installation in solid wall without clearance

Installation of the ERK-SO directly next to

one another in solid walls

(additional accessory package required)

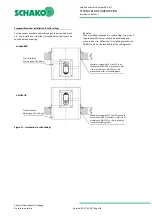

Plunge

View

View