Smoke extraction damper ERK-SO

TECHNICAL DOCUMENTATION

Models

and

dimensions

|

Construction subject to change

No

return

possible

Version:

2017-11-28

|

Page

7

Use

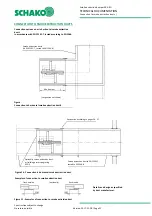

The smoke extraction damper type ERK-SO can be fitted as

shown in the following table.

1)

when installed next to each other

2)

when installed on top of each other

3)

in connection with mounting brackets WE-S and on-

site suspensions and horizontal damper blade axle

Table 3 - Usability

General information

o

During mounting or installation, there is a risk of in-

juries. To avoid injuries, personal protective equip-

ment (PPE) must be worn.

o

Smoke extraction dampers must be installed such

that external forces do not impair their functioning.

During mounting it may be required to provide rein-

forcements for the housing or the like. The require-

ment of statically load-bearing lintels may have to be

taken into consideration.

o

Improper transport/handling may result in dam-

age/functional impairment. In addition to that, the

film of the transport packaging must be removed

and the delivery inspected for completeness.

o

In storage, smoke extraction dampers must be pro-

tected from dust, dirt, moisture and the effects of

extreme temperatures. They must not be exposed to

direct effects of the weather.

4)

in connection with ceiling frame DR-S

5)

in connection with on-site suspensions

6)

in connection with on-site fastening frames and suspen-

sions

o

The smoke extraction dampers must be protected

from dirt and damage. After installation is complete,

any dirt must be removed immediately.

o

Enough space must be provided for installation, mor-

tar lining, etc.

o

Carry out a functional check of the smoke extraction

damper before and after mounting and ensure ready

access.

o

Electrical installations or work on electrical compo-

nents may only be carried out by skilled electricians.

The supply voltage must be switched off when per-

forming this work.

o

Always check whether the housing needs to be ex-

tended on the b side (MS) for the corresponding in-

stallation situations (e.g. the thickness of the sup-

porting structure and a possible connection to the

smoke extraction duct must be considered).

Use

Instal-

lation

Material/Model

Mini-

mum

thickness

[

mm

]

Minimum distance

of two ERK-SO

from one another

[

mm

]

Fire resistance

class

For no-

tes, see

page

WALL

solid

Apparent

density

≥

450 kg/m³

in

for example, concrete, masonry ac-

cording to EN 1996 or DIN 1053; solid

plaster wall boards according to EN

12859 or DIN 18163

100

0 (4)

1)

200

2)

EI 90(v

ew

,i

↔

o)S

1000 C

10000

MA multi

8

on

3)

for example, concrete, masonry ac-

cording to EN 1996 or DIN 1053; solid

plaster wall boards according to EN

12859 or DIN 18163

100 200

EI 90(v

ew

,i

↔

o)S

1000 C

10000

MA multi

14

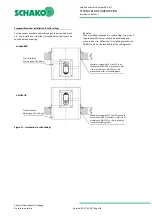

CEILING

solid

Apparent

density

≥

650±200

kg/m³

in

3)

for example, concrete, aerated con-

crete

150 200

EI 90(h

ow

,i

↔

o)S

1000 C

10000

MA multi

17

to

4)

for example, concrete, aerated con-

crete

150 200

EI 90(h

ow

,i

↔

o)S

1000 C

10000

MA multi

20

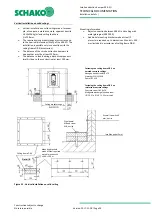

SMOKE EXT

R

ACTI

ON

DUCT

horizontal

Apparent

density

≥

520 kg/m³

in

5)

in accordance with EN 12101-7,

tested according to EN 1366-8

35 200

EI 90(v

ed

,i

↔

o)S

1000 C

10000

MA multi

21

on

5)

in accordance with EN 12101-7,

tested according to EN 1366-8

35 200

EI 90(v

ed

,i

↔

o)S

1000 C

10000

MA multi

21

to

6)

in accordance with EN 12101-7,

tested according to EN 1366-8

35 200

EI 90(v

ed

,i

↔

o)S

1000 C

10000

MA multi

22