-22-

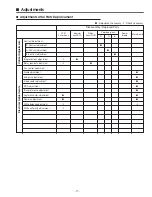

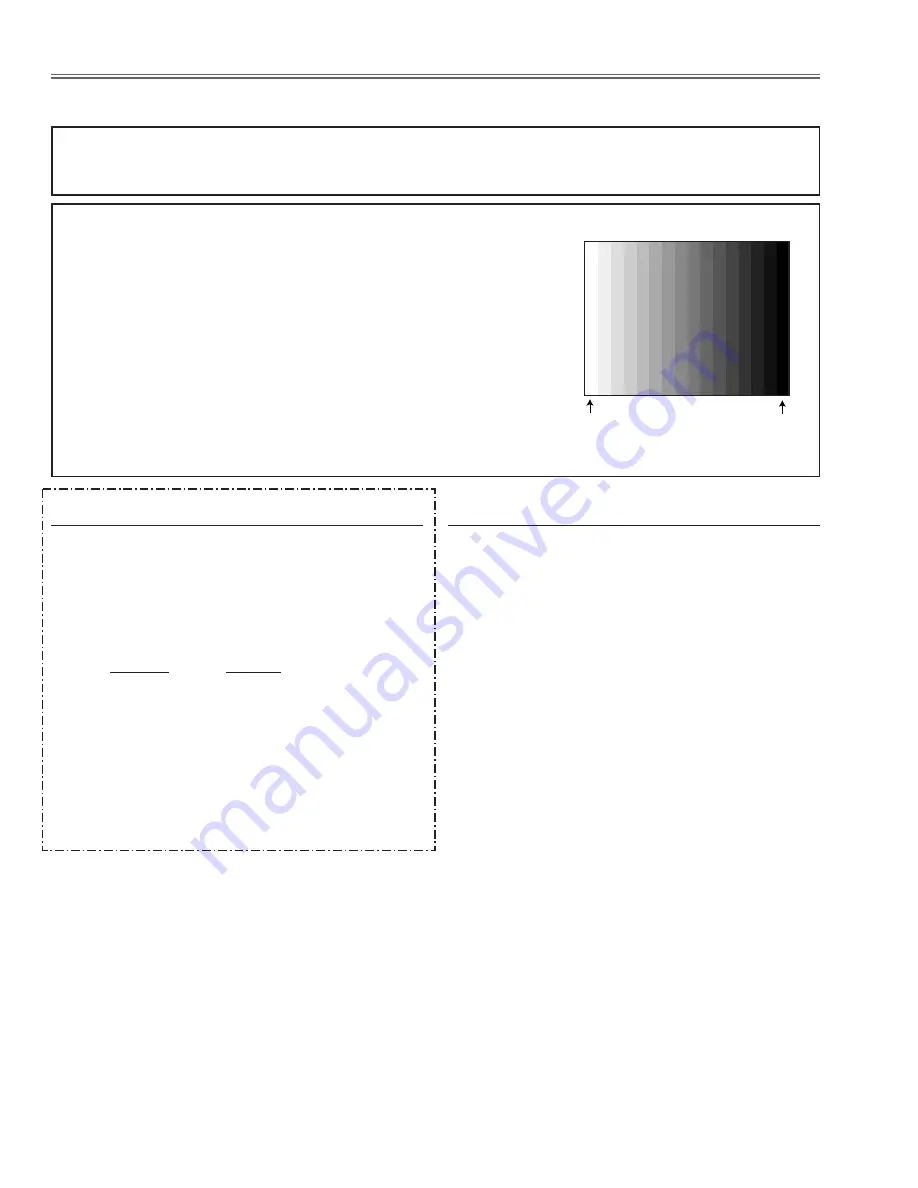

[Adjustment Condition]

●

Input signal

Video signal .......................... 1.0Vp-p/75

Ω

terminated, 16 steps gray

scale (Composite video signal)

Computer signal .................... 0.7Vp-p/75

Ω

terminated, 16 steps gray

scale pattern

Component Video signal ...... 0.7Vp-p/75

Ω

terminated, 16 steps gray

scale (Component video signal with

480p, 575p, 720p or 1080i format)

●

Picture control mode .............. “STANDARD” mode unless otherwise

noted.

Note:

* Please refer to “Service Adjustment Menu Operation” for entering the service mode and adjusting the service

data.

White 100%

Black 100%

●

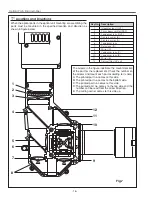

Circuit Adjustments

CAUTION: The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the follow-

ing adjustments except requiring the readjustments in servicing otherwise it may cause loss of per-

formance and product safety.

Electrical Adjustments

16 steps gray scale pattern

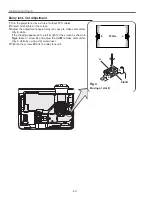

After replacing the Power Board readjust the Output

voltage adjustment as follows.

1. Connect a digital voltmeter to pins 1 (+) and 3 (-) of

K6D

.

2. Adjust the voltage by using

VR611

as following.

AC Input

Reading

230V 380V

±2V

Caution:

Be sure to connect the lamp when taking this adjust-

ment.

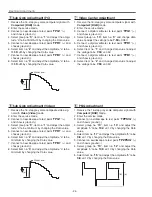

Output Voltage adjustment

1. Set the lamp mode to "Normal" and then enter the

service mode.

2. Select group no. “

111

”, item no. “

5

” and set data value

to “

1

”.

3. Connect a digital voltmeter to test point “

TP12V1

” (+)

and chassis ground (-). Select item no. “

89

” and

change data value to adjust voltage to be

7.0

±0.1V.

4. Connect a digital voltmeter to test point “

TP12V2

”

(+) and chassis ground (-). Select item no. “

91

” and

change data value to adjust voltage to be

7.0

±0.1V.

5. Connect a digital voltmeter to test point “

TP12V1

” (+)

and chassis ground (-). Select item no. “

90

” and

change data value to adjust voltage to be

13.5

±0.1V.

6. Connect a digital voltmeter to test point “

TP12V2

” (+)

and chassis ground (-). Select item no. “

92

” and

change data value to adjust voltage to be

13.5

±0.1V.

7. Select item no. “

5

” and set data value to “

0

”.

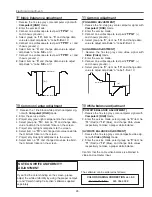

z

Fan Control adjustment

* This adjustment is not required even if the power

board is replaced because this adjustment is carried

out before parts shipment.

Summary of Contents for PLC-XU50

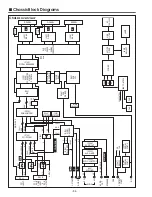

Page 51: ... 51 IC Block Diagrams AD8075 Selector IC201 AN7513 Audio Output IC5601 ...

Page 52: ... 52 BA7078 Sync Separator IC5341 IC Block Diagrams AN5870 RGB SYNC SW IC1201 IC5201 ...

Page 54: ... 54 FA5502 P F Control IC621 IC Block Diagrams CXD3536 LCD Driver IC401 ...

Page 55: ... 55 IC Block Diagrams M62392 M62393 D A IC6271 IC281 ML60851 USB Driver IC9801 ...

Page 56: ... 56 STR Z2156 Power Switching Control IC631 TB1274 Video Decoder IC3101 IC Block Diagrams ...

Page 57: ... 57 IC Block Diagrams TC90A69F Y C Separator IC2101 ...

Page 86: ...MW3 XU5000 MT3 XU5500 86 S5 S5 S5 L9 Projection Mechanical Parts List ...

Page 89: ...MW3 XU5000 MT3 XU5500 89 ...

Page 90: ... MT3A Sep 2003 BB 400 Printed in Japan SANYO Electric Co Ltd ...