(26) 1200 PSI Hard Surface Extractor

1200 PSI Hard Surface Extractor (15)

5.0 Set-Up and Operation Continued

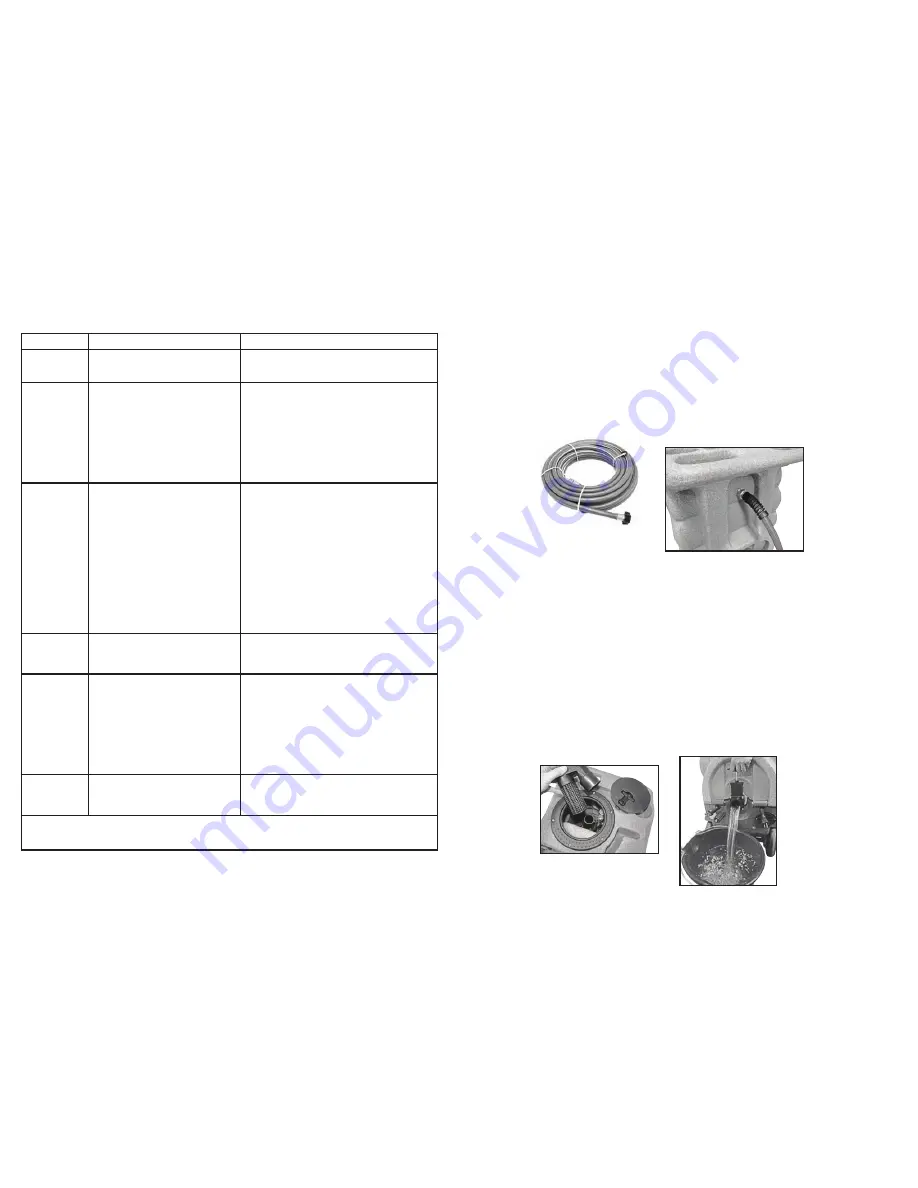

5.6 Connection of Auto-Dump Hose

The auto-dump hose is a 50-foot section of a 3/4” garden hose.

• Remove the cap from the auto-dump outlet fitting on the back of the machine.

• Connect the auto-dump hose to the outlet fitting.

• Place the other end of the hose in a commode or drain connected to a sanitary sewer

system.

• Secure the hose end to prevent movement during pumping.

Use defoamer to prevent foam build-up in the recovery tank during cleaning and to

keep foam/moisture from entering vacuums.

If not using the auto-dump feature, the auto-dump hose does not need to be connected.

When the recovery tank fills during cleaning, the float ball assembly in the vacuum inlet

filter will rise and will automatically shut-off the vacuum air flow to prevent the recovery

tank from overfilling and waste from getting into the vacuums. When this occurs:

• Immediately turn OFF the vacuum switches.

• Drain the recovery tank. Turn OFF the pump switch while draining the tank. Turn

pump switch back ON upon resumption of cleaning.

• Close the dump valve and turn the vacuum switches back ON when ready to resume

cleaning.

If the auto-dump or vacuum shut-off is not working properly, refer to the “Trouble

Shooting Guide” section or contact your distributor for advice or assistance.

50-Foot Auto-Dump Hose

Part No. 80-0112

Float Assembly

Part No. 80-0012

Drain Recovery Tank

8.0 Trouble Shooting Guide

Never operate the Hard Surface Extractor when the equipment is not performing as

expected or when any part is visibly damaged. When repair is needed, take the equipment

to an authorized service center.

Problem

Possible Cause

Remedy

Machine Not

Turning On –

No Power

1.

Building circuit breaker tripped

2.

Faulty power cord

3.

Faulty switches or internal wiring

1.

Reset breakers or move cords to other outlets

2.

Replace power cord

3.

Check wiring and test switches – repair as needed

Solution Pump not

Running

1.

Building circuit breaker tripped

2.

Pump circuit breaker tripped

3.

Faulty power cord

4.

Faulty switches or internal wiring

5.

Pump motor breaker tripped

6.

Pump motor faulty

7.

Pump seized – trips breaker

1.

Reset breakers or move cords to other outlets

2.

Reset breaker – check available circuit power and

pump

3.

Replace cord

4.

Check wiring and test switches – repair as needed

5.

Push in reset button on pump motor and/or external

breaker

6.

Replace pump motor

7.

Repair or replace pump head and bearing – check

motor and/or replace complete pump and motor

assembly

Low Solution

Pressure and/or

Pulsation

1.

Jets too large for pressure desired

2.

Jets worn allowing too much flow

3.

Solution inlet filter plugged

4.

Hose from solution tank restricted

5.

Pump intake hose or fittings leaking

6.

Pressure regulator sticking

7.

Pressure regulator faulty

8.

Filter screen or jets plugged on tool

9.

Solution tank empty

10.

Pump not primed

11.

Pump faulty

12.

Pressure gauge faulty

13.

Tool valve faulty

14.

Quick disconnects or hoses restricted

1.

Check jet size and flow rates – use smaller jets or

lower pressure

2.

Replace jets

3.

Clean or replace filter

4.

Repair or replace hose

5.

Repair or replace hose – tighten clamps or replace

fittings

6.

Lube o-rings on regulator shaft

7.

Repair or replace pressure regulators

8.

Clean out filter or jets

9.

Add water to tank – check and repair auto fill as-

sembly

10.

Perform pump priming procedure

11.

Repair or replace pump

12.

Replace gauge

13.

Repair or replace valve

14.

Clean out or replace quick disconnects and/or hoses

Can’t Connect

Solution Hose to

Machine

1.

Pressure in lines

2.

Quick disconnects faulty

3.

Wrong style/size quick disconnects

1.

Replace pressure

2.

Replace quick disconnects

3.

Replace quick disconnects to match connects on

machine

Auto-Dump Pump-

Out not Working

1.

Building circuit breaker tripped

2.

Faulty power cord

3.

Faulty switches or internal wiring

4.

Auto-dump pump-out pump faulty

5.

Auto-dump pump-out pump clogged

6.

Outlet check valve stuck

7.

Discharge hose restricted

8.

Float switch stuck

9.

Float switch faulty

1.

Reset breakers or move cords to other outlets

2.

Replace cord

3.

Check wiring and test switches – repair as needed

4.

Replace auto-dump pump-out pump

5.

clean auto-dump pump-out – keep recovery tank

clean – use hydro-filter

6.

Clean or replace check valve

7.

Un-kink, clean-out or replace hose

8.

CLean switch – make sure float slides up and down

easily

9.

Replace float switch

Vacuum Motor not

Running

1.

Building circuit breaker tripped

2.

Faulty power cord

3.

Faulty switches or internal wiring

4.

Vacuum motor faulty

1.

Reset breakers or move cords to other outlets

2.

Replace cord

3.

Check wiring and test switches – repair as needed

4.

Replace vacuum motor

To reduce the risk of fire, electrical shock or injury, repairs to wiring should only be performed by experienced service technicians. If

you are not experienced in checking electrical wiring, contact your nearest authorized service center to perform tests and repairs to

wiring and switches.

https://harrissupplyind.com - To Order Parts Call 608-268-8080