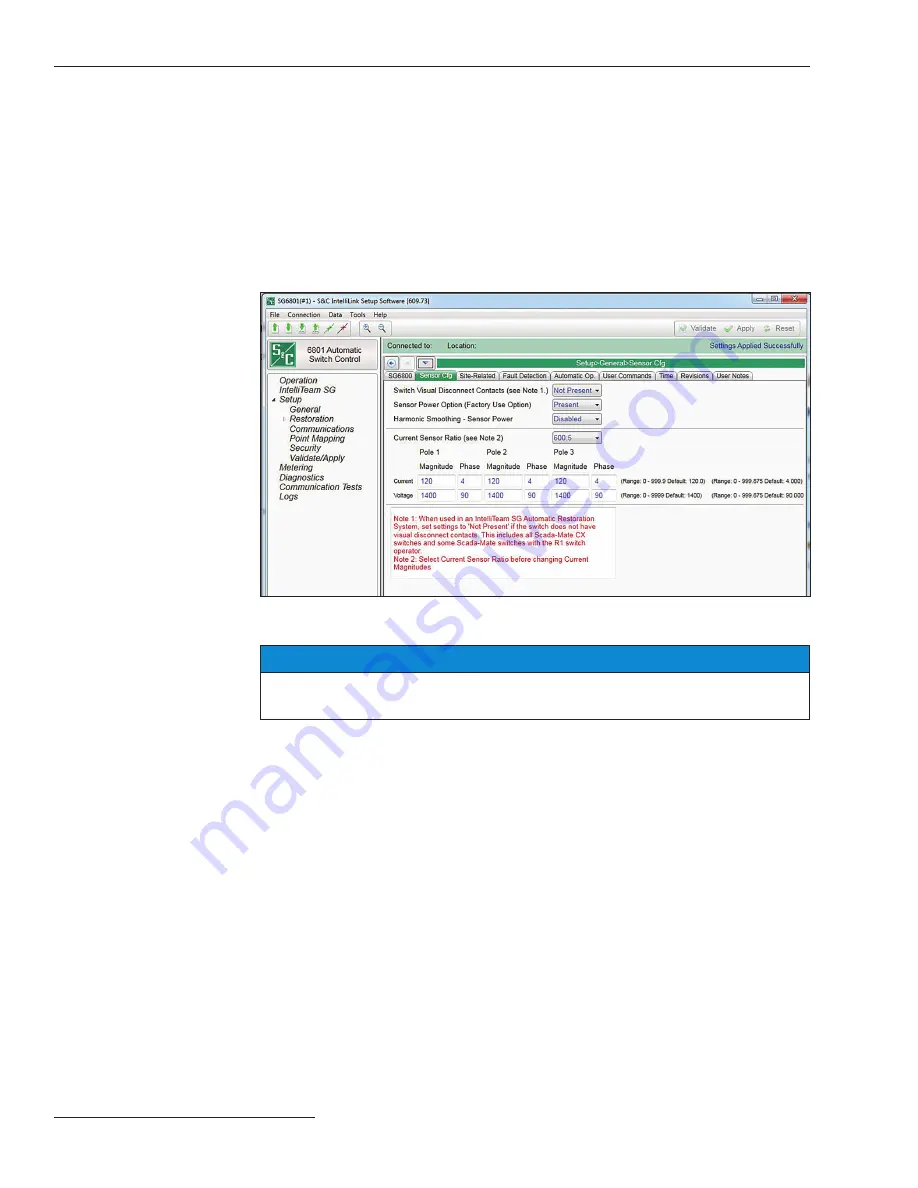

Switch Control Configuration

Click on the

Sensor Config

tab. See Figure 8. This screen configures sensor calibration

data for Scada-Mate Switching Systems, and PME, PMH, or Vista Underground

Distribution Switchgear sensors. The switch control uses this data to calibrate sensor

input to the voltage and current amplitude accuracy specified for S&C Sensors. The 6802

and 6803 controls are supplied with a yellow sheet showing the current and voltage ratio

information (also stamped on each sensor). Enter the information on this screen.

The 6801 controls do not have this card, but the information is part of the data package

provided with the Scada-Mate switch. Because the controls and switches are typically

shipped separately it is important to make sure the information stays with the switch

until it is pared with a control.

Sensor Configuration

Figure 8. The Setup>General>Sensor Configuration screen (6801 switch control shown).

NOTICE

Ratios must be entered for phase B when phases A, B, and C are measured . The

phase B ratios are used to adjust all voltage scales for 15-, 25-, or 35-kV systems .

12 S&C Instruction Sheet 1045-511