S&C Instruction Sheet 1041-550

3

Safety Information

Understanding

Safety-Alert Messages

Following

Safety Instructions

Replacement

Instructions and Labels

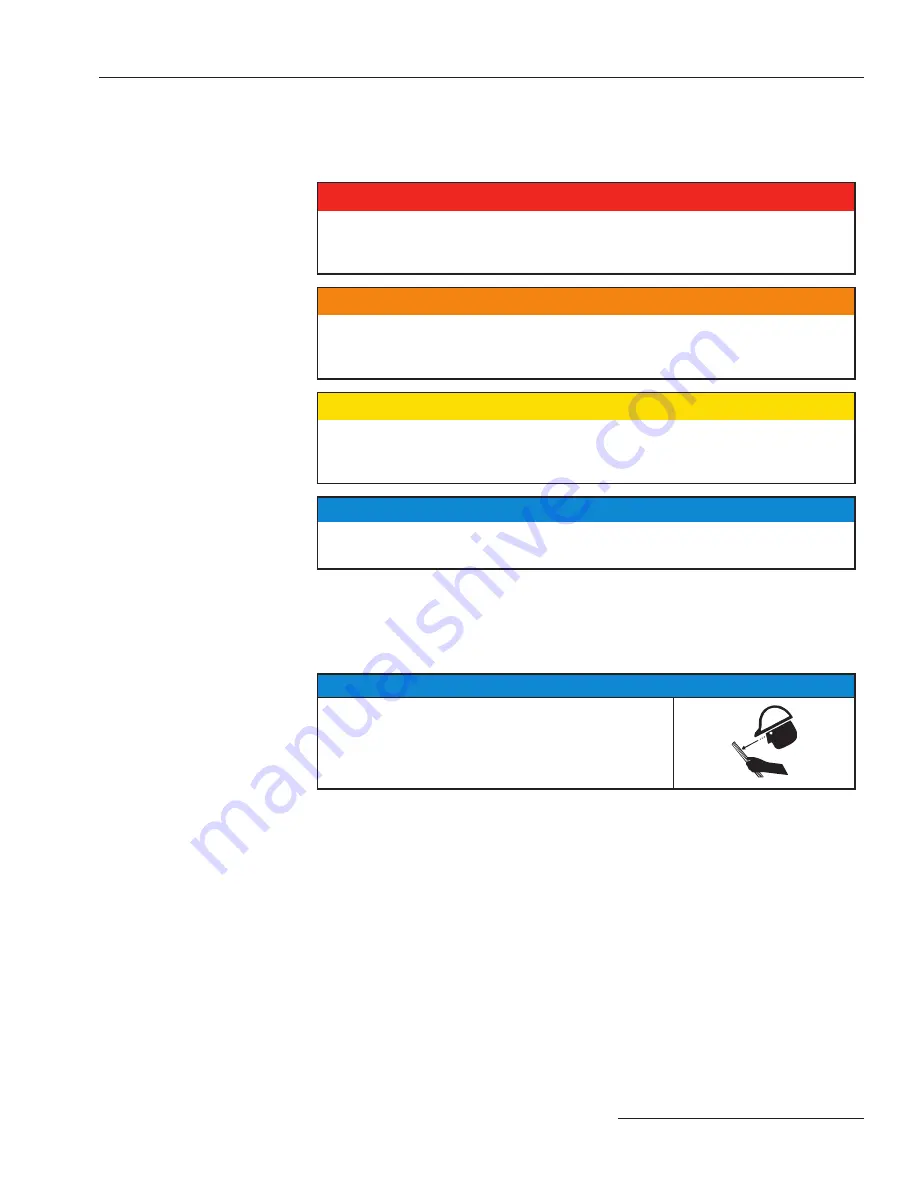

There are several types of safety-alert messages which may appear throughout this

instruction sheet as well as on labels attached to the

5800 Series Control

. Familiarize

yourself with these types of messages and the importance of the various signal words,

as explained below

.

Ç

DANGER

“DANGER” identifies the most serious and immediate hazards which

will likely

result in serious personal injury or death if instructions, including recommended

precautions, are not followed.

Ç

WARNING

“WARNING” identifies hazards or unsafe practices which

can

result in serious

personal injury or death if instructions, including recommended precautions, are

not followed.

Ç

CAUTION

“CAUTION” identifies hazards or unsafe practices which

can

result in minor per-

sonal injury or product or property damage if instructions, including recommended

precautions, are not followed.

NOTICE

“NOTICE”

identifies important procedures or requirements that

can

result in product

or property damage if instructions are not followed.

If you do not understand any portion of this instruction sheet and need assistance,

contact your nearest S&C Sales Office or S&C Authorized Distributor. Their tele-

phone numbers are listed on S&C’s website www.sandc.com. Or call S&C Headquarters

at (773) 338-1000; in Canada, call S&C Electric Canada Ltd. at (416) 249-9171.

NOTICE

Read this instruction sheet thoroughly and carefully

before installing or operating your S&C 5800 Series

Automatic Switch Control.

If you need additional copies of this instruction sheet, contact your nearest S&C Sales

Office, S&C Authorized Distributor, S&C Headquarters, or S&C Electric Canada Ltd.

It is important that any missing, damaged, or faded labels on the equipment be replaced

immediately. Replacement labels are available by contacting your nearest S&C Sales Office,

S&C Authorized Distributor, S&C Headquarters, or S&C Electric Canada Ltd.

Summary of Contents for 5800 Series

Page 34: ...Printed in U S A...