Summary of Contents for RL60GG Series

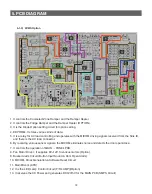

Page 75: ...75 5 PCB DIAGRAM 5 3 Connector Layout and Description Main Board 5 3 1 Q G J OPTION...

Page 76: ...76 5 PCB DIAGRAM 5 3 2 R P Z H Option...

Page 77: ...77 5 PCB DIAGRAM 5 3 3 L Option...

Page 78: ...78 5 PCB DIAGRAM 5 3 4 W E Option...

Page 80: ...80 5 PCB DIAGRAM IPM DIODE VOLTAGE 5 5 IPM Diode Voltage...

Page 81: ...81 6 WIRING DIAGRAM 6 1 Q G J OPTION...

Page 82: ...82 6 WIRING DIAGRAM 6 2 R P Z H Option...

Page 83: ...83 6 WIRING DIAGRAM 6 3 L Option...

Page 84: ...84 6 WIRING DIAGRAM 6 4 W E Option...

Page 85: ...85 6 WIRING DIAGRAM 6 5 S Option...

Page 86: ...86 7 CIRCUIT DIAGRAM 7 1 Schematic Diagram PBA Main 7 1 1 Q G J OPTION...

Page 87: ...87 7 CIRCUIT DIAGRAM 7 1 2 R P Z H L Option...

Page 88: ...88 7 CIRCUIT DIAGRAM 7 1 3 W E S Option...

Page 89: ...89 7 CIRCUIT DIAGRAM 7 2 Schematic Diagram PBA Inverter...

Page 90: ...90 7 CIRCUIT DIAGRAM 7 3 Block Diagram PBA Main...

Page 91: ...91 7 CIRCUIT DIAGRAM 7 4 Block Diagram PBA Inverter G H L P R Z Option...

Page 92: ...92 7 CIRCUIT DIAGRAM 7 5 Block Diagram PBA Inverter Q J Option...