57

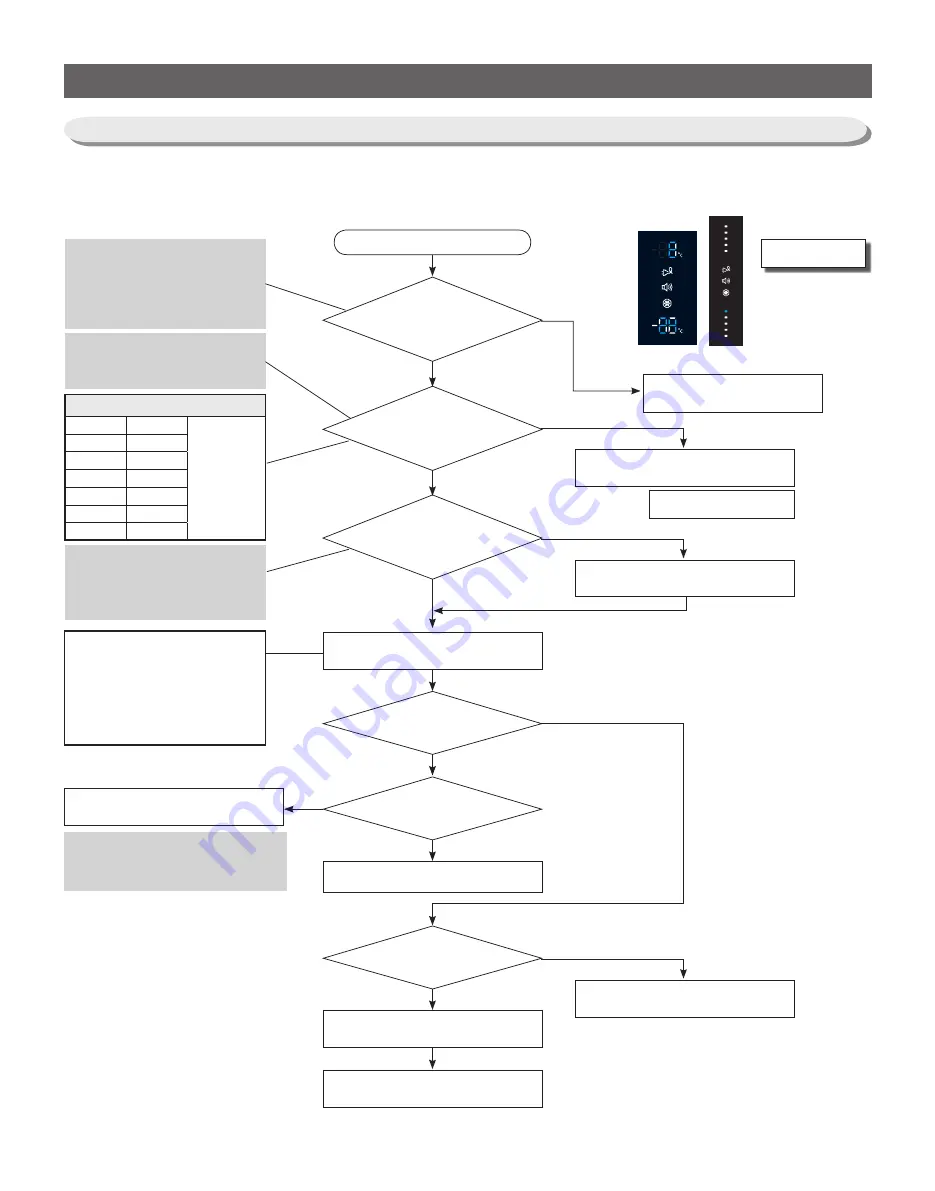

4. TROUBLESHOOTING

Defrost Sensor is normal?

(Check it with Self-Diagnosis)

The Sensor Temperature Value

is lower than 12

℃

.

After heating up

for a while, it goes back to

Cooling Operation

MAIN PCB

Connection is normal?

Power is applied to

F-Defrost Heater.

Start

Do Forced Defrost

Normal

Check Bimetal, Heater Wire

Cut or Wire Contact

Repair Defective Relay or

replace PCB Assy

Replace the Sensor

Forced Operation for a while

Repair Connector

Check the related sensors

if they are defective.

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

☞ When checking

with the Self

Diagnosis

F DEF. ERROR

Temp vs. Resistance Table

30

℃

4.22

㏀

For more

detail data,

refer to

DATA1. Temp

Table

20

℃

6.05

㏀

10

℃

8.87

㏀

0

℃

13.29

㏀

-10

℃

20.42

㏀

-20

℃

32.23

㏀

-30

℃

52.41

㏀

** Sensor Resistance Reading Location **

F-DEF : Between CN30 #4

↔

CN72 #10

** 0Ω : Short / ∞Ω : Open

** Sensor Resistance Reading Location **

F-DEF : Between PCB COMMON Ground

and CN30 #4 (or Sensor Marking #2(R302)

** 0Ω : Short / ∞Ω : Open

Note When the temperature of the F DEF Sensor

goes over 12

℃

with the Defrost Heater heating up,

it stops heating and it goes back to Cooling Operation.

When the Freezer button is pressed

after pressing the Freezer and the

Fridge buttons at the same time for 6

seconds, it will enter into the Test Mode.

And, when any button is pressed twice,

it will enter into the Forced Defrost and

"Fd" lights up on the Display Panel.

** Heater Resistance Reading Location **

F-DEF : Resistance between CN70 #1(BLK)

↔

CN70 #5 (White) should be 260 ohm ± 10%.

** 0Ω : Short / ∞Ω : Open

(Bimetal / Thermal Fuse / Heater Defect)

Refer to Self-Diagnosis

Check Bimetal, Heater

Continuity or Wire Connection

All Defrost Heaters

are normal?

Yes

No

4-2-4) When Defrost does not work (F DEF Heater)

- When there is a trouble in defrosting, select the Self-Diagnosis function before turning off the unit.

And, check if there is any defect in the Defrost Heater. If not, plug out the unit and do the Trouble-Shooting.

(Refer to the Self-Diagnosis function and check the details)

BAR-TYPE

7-Segment

Summary of Contents for RL60GG Series

Page 75: ...75 5 PCB DIAGRAM 5 3 Connector Layout and Description Main Board 5 3 1 Q G J OPTION...

Page 76: ...76 5 PCB DIAGRAM 5 3 2 R P Z H Option...

Page 77: ...77 5 PCB DIAGRAM 5 3 3 L Option...

Page 78: ...78 5 PCB DIAGRAM 5 3 4 W E Option...

Page 80: ...80 5 PCB DIAGRAM IPM DIODE VOLTAGE 5 5 IPM Diode Voltage...

Page 81: ...81 6 WIRING DIAGRAM 6 1 Q G J OPTION...

Page 82: ...82 6 WIRING DIAGRAM 6 2 R P Z H Option...

Page 83: ...83 6 WIRING DIAGRAM 6 3 L Option...

Page 84: ...84 6 WIRING DIAGRAM 6 4 W E Option...

Page 85: ...85 6 WIRING DIAGRAM 6 5 S Option...

Page 86: ...86 7 CIRCUIT DIAGRAM 7 1 Schematic Diagram PBA Main 7 1 1 Q G J OPTION...

Page 87: ...87 7 CIRCUIT DIAGRAM 7 1 2 R P Z H L Option...

Page 88: ...88 7 CIRCUIT DIAGRAM 7 1 3 W E S Option...

Page 89: ...89 7 CIRCUIT DIAGRAM 7 2 Schematic Diagram PBA Inverter...

Page 90: ...90 7 CIRCUIT DIAGRAM 7 3 Block Diagram PBA Main...

Page 91: ...91 7 CIRCUIT DIAGRAM 7 4 Block Diagram PBA Inverter G H L P R Z Option...

Page 92: ...92 7 CIRCUIT DIAGRAM 7 5 Block Diagram PBA Inverter Q J Option...