5. Parameters

5-65

5.8.3 Stall prevention

• Stall occurs when the rotor cannot keep up with the rotating magnetic

field on the motor start side.

e.g. a large load is applied to the motor and sudden acceleration or

deceleration is performed, etc.

5.8.3.1 Stall prevention at start : P2.01

Parameter

No.

Name

Unit

Setting

range

Factory

Setting

Changeable

during

operation

P2.01

Stall

Prevention

at Start

- 0~1 1

X

• P2.01 can be used to set the stall prevention function at start.

• Setting

Setting

constant

Function

0

Disabled

(The motor with excessive load is possibly stalled. Then a longer

acceleration time and reduced load is required.)

1 Enabled

• When setting 1 is selected, acceleration is stopped if the motor current

exceeds the acceleration stall prevention level(P2.02). Acceleration is

started again when the current falls below this level. The actual

acceleration time can be longer than the set value (at F2.01) depending

on the load.

5.8.3.2 Stall prevention level at start : P2.02

Parameter

No.

Name

Unit

Setting

range

Factory

Setting

Changeable

during

operation

P2.02

Stall

Prevention

Level at Start

1% 0~200 170

O

• P2.02 can be used to set the output current limit level as a percentage of

rated current of the inverter at start.

(i.e. 100% corresponds to the rated current of the inverter)

• This setting is valid when P2.01 is let to 1.

• Normally it isn’t necessary to change this setting.

5-66

MOSCON-E7 User’s Manual

• Decrease this setting when:

- The motor capacity is small compared to the inverter capacity

- Stall occurs when the motor is operated with the factory setting

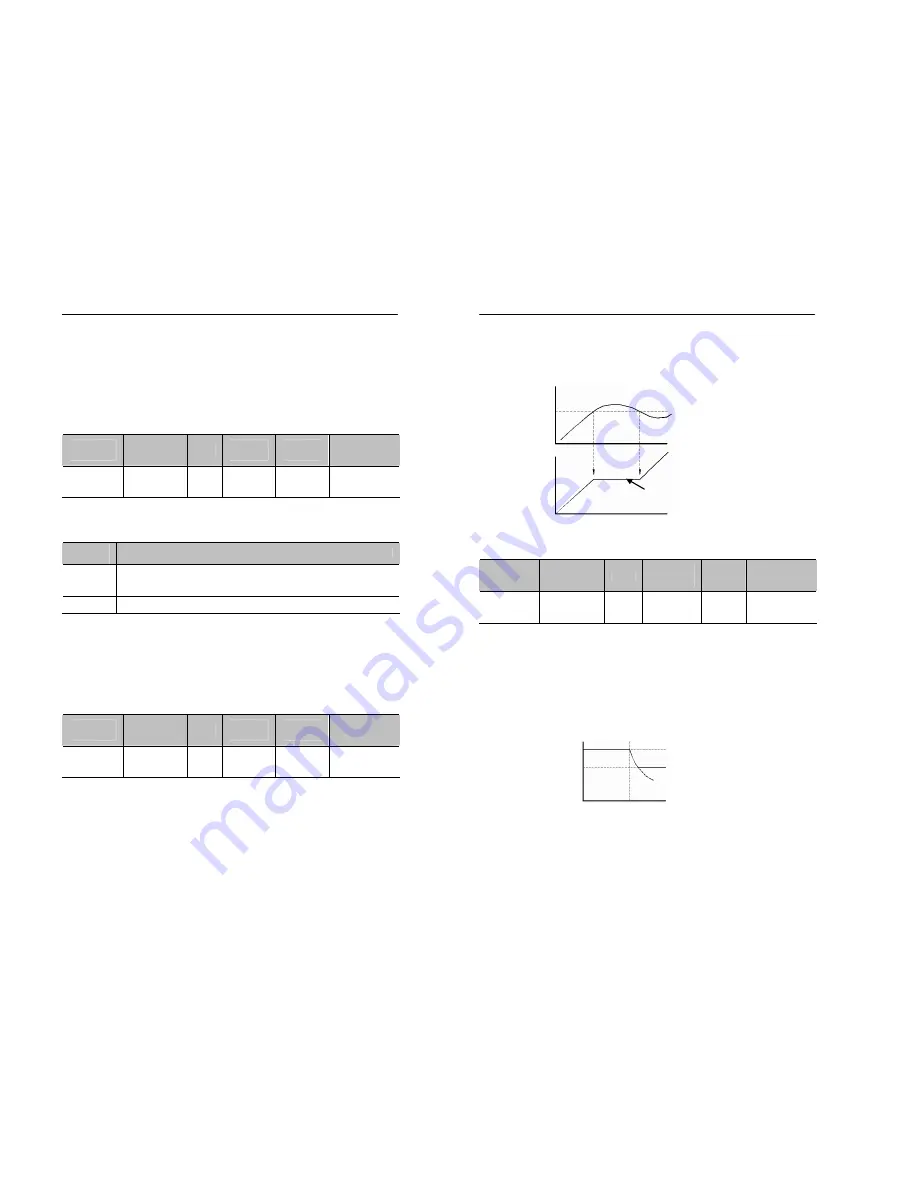

Figure 5.25 Acceleration Stall Prevention function : P2.01=1

5.8.3.3 Stall prevention limit during acceleration : P2.03

Parameter

No.

Name

Unit

Setting

range

Factory

Setting

Changeable

during

operation

P2.03

Stall

Prevention at

Acc. Limit

1% 0~100 50

O

• P2.03 can be used to set the stall prevention limit when high-speed

motor is being used in the high-speed range

(the high frequency range above the base frequency)

• Normally it isn’t necessary to change this setting.

• The standard target setting is the motor’s rated current.

• Set P2.03 as a percentage of the inverter’s rated current.

(i.e. 100% corresponds to the inverter’s rated current)

Figure 5.26 Stall prevention limit during acceleration

Acceleration stall

prevention level

C0.01

P2.02

P2.03

Base frequency (FA)

(Acceleration stall

prevention level)

(Acceleration stall

prevention limit)

Output frequency

Time

Time

Output

current

Output

frequency

P2.02

(Acceleration stall prevention level)

The output frequency is

controlled to prevent stall