EB 6493 EN

17-7

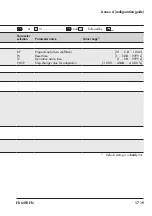

Annex A (configuration guide)

…

……………

or

……………………………………

………………… ……………………………

or

……………………

and

, followed by

Menu Function -CO-

Setting

options

1)

Description of functions

Parameter level -PA-

Parameter

selection

Parameter name

Value range

1)

Set point

SETP

SP.VA

Internal set point W

on W

ON

SP.VA/W

W

WINT

WINT

WRAN

WRAN

Internal set point

Lower measuring range value W/W2

Upper measuring range value W/W2

Lower adjustment limit W/W2

Upper adjustment limit W/W2

[

WRAN …

0.0

…

WRAN]

[–999 …

0.0

…

WINT]

[

WINT …

100.0

… 9999]

[

WINT …

0.0

…

WRAN]

[

WRAN …

100.0

…

WINT]

2)

Internal set point W2

oFF W2

on W2

OFF

ON

P.VA/W2

W2

Internal set point

[

WRAN …

0.0

…

WRAN]

2)

Input variable WE

oFF WE

on WE

F01 WE

OFF

External set point WE

Input for external feedback with

three-step output

noPA SP.VA/WE

No

parameters

F02 WE

Input for feedforward control

SP.FU

Set point ramp

oFF RAMP

OFF

F01 RAMP

Started with actual value by binary

input BI1

SP.FU/RAMP

TSRW

Running time

[1 …

10

… 9999 s]

F02 RAMP Started with WIRA by binary input

BI1

SP.FU/RAMP

WIRA

Initial value

[

WINT …

0.0

…

WINT]

2)

F03 RAMP

Without start conditions

Set point switchover

oFF CH.SP

F01 CH.SP

OFF

W(W2)/WE by binary input BI1

noPA SP.VA/CH.SP

No parameter

F02 CH.SP W/W2 by binary input BI1

1)

Default setting is in

bold

print.

1)

Default setting is in

bold

print.

2)

Decimal place depends on DP function (AUX menu

Summary of Contents for Trovis 6493

Page 6: ...Contents EB 6493 EN...

Page 22: ...3 10 EB 6493 EN...

Page 30: ...5 6 EB 6493 EN...

Page 36: ...6 6 EB 6493 EN...

Page 72: ...8 12 EB 6493 EN...

Page 84: ...11 2 EB 6493 EN...

Page 86: ...12 2 EB 6493 EN...

Page 88: ...13 2 EB 6493 EN...

Page 90: ...14 2 EB 6493 EN...

Page 92: ...15 2 EB 6493 EN...

Page 95: ...EB 6493 EN 16 3 Certificates TR CU certificate...

Page 96: ...16 4 EB 6493 EN Certificates...

Page 97: ...EB 6493 EN 16 5 Certificates...

Page 98: ...16 6 EB 6493 EN...

Page 125: ......

Page 126: ......

Page 127: ......