5-12

EB 8355-2 EN

Installation

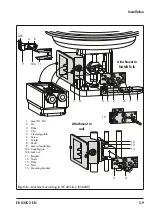

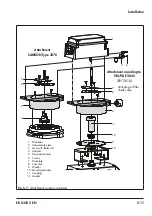

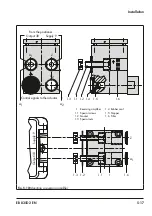

b) Mounting the intermediate

piece

SAMSON Type 3278 Actuator

1. Fasten the adapter (4) to the free shaft

end of the rotary actuator.

2. Fasten the intermediate piece (2) to the

actuator housing using two screws.

Align the intermediate piece so that the

air connections of the positioner point to-

ward the diaphragm case side.

3.

Align the cam disk (8) and scale (7) as

described in section 5.3.3 and fasten.

Actuators according to VDI/VDE 3845

(09/2010),

fixing level 2

1. Place the assembled intermediate piece

(2, 9, 11 and 12) onto the mounting

bracket included in the scope of actuator

delivery and fasten.

2.

Align the cam disk (8) and scale (7) as

described in section 5.3.3 and fasten.

c) Basic setting of the cam disk

The valve model used determines the basic

setting of the cam disk.

Cam disks tailored to the special characteris-

tic of a valve cause the valve to open in a

non-linear or non-equal percentage way.

The visible difference between the set point

(4 to 20 mA) and the actual position (open

-

ing angle) does not constitute a system devi

-

ation of the positioner.

and

show linear cam disks.

illustrates a control valve assembly

with a rotary actuator with spring-return

mechanism that opens counterclockwise. The

arrangement of the springs in the actuator

determines the fail-safe position of the valve.

shows how to adjust the cam disk

when a double-acting springless rotary actu-

ator is used. The direction of rotation (either

counterclockwise or clockwise) depends on

the actuator and valve model used. The cam

disk must be set when the valve is closed.

Each cam disk carries two cam sections

whose starting points are indicated by small

holes. Depending on how the rotary actuator

operates (air-to-open or air-to-close), the

starting point of the cam, either marked

N

(standard characteristic) or

I

(reverse charac-

teristic), must point towards the lever with

feeler roll. When the starting point is located

on the back of the cam disk, turn over the

cam disk.

Î

Align the 0° position on the scale to cor

-

respond with the actuator's closed posi-

tion.

In this case, for fail-open actuators and

for springless actuators, apply the maxi-

mum supply pressure to the actuator be-

fore aligning the cam disk.

Î

Align the starting point (hole) of the cam

selected so that the fulcrum of the cam

disk and 0° position on the scale as well

as the arrow on the window are in line

with each other.

Î

When aligning the cam disk, clip the

double-sided scale disk on the cam disk,

Single-acting rotary actuator with spring-return mechanism

Linear cam disk

(equal percentage cam disk is represented by a broken and dotted line)

Control valve opens counterclockwise

For valves that open clockwise, the cam disk must be turned over so that lever with feeler roll moves

over the same disk segments as shown in the images below, but with the cam disk turning clockwise.

Fail-safe action:

fail-close valve

Operating direction increasing/increasing >>

Operating direction increasing/decreasing <>

Set point

Signal pressure

Valve

Characteristic

Set point

Signal pressure

Valve

Characteristic

increases

increases

opens

N

decreases

increases

opens

I

90˚

60˚

30˚

0˚

90˚

60˚

30˚

0˚

Feeler roll

Starting point

N

Starting point

I

Hole to secure the cam disk

Insert clip and press the flaps

outwards

Fail-safe action:

fail-open valve

Operating direction increasing/increasing >>

Operating direction increasing/decreasing <>

Set point

Signal pressure

Valve

Characteristic

Set point

Signal pressure

Valve

Characteristic

decreases

decreases

opens

I

increases

decreases

opens

N

90˚

60˚

30˚

0˚

90˚

60˚

30˚

0˚

Feeler roll

Starting point

N

Starting point

I

Alignment at max. signal pressure

Fig. 5-8:

Cam disk settings for single-acting actuators

Note

Summary of Contents for 3767

Page 10: ...1 6 EB 8355 2 EN...

Page 14: ...2 4 EB 8355 2 EN...

Page 58: ...6 2 EB 8355 2 EN...

Page 60: ...7 2 EB 8355 2 EN...

Page 70: ...10 2 EB 8355 2 EN...

Page 72: ...11 2 EB 8355 2 EN...

Page 74: ...12 2 EB 8355 2 EN...

Page 76: ...13 2 EB 8355 2 EN...

Page 78: ...14 2 EB 8355 2 EN...

Page 79: ...EB 8355 2 EN 14 3...

Page 80: ...14 4 EB 8355 2 EN...

Page 81: ...EB 8355 2 EN 14 5...

Page 88: ...14 12 EB 8355 2 EN...

Page 89: ...EB 8355 2 EN 14 13...

Page 90: ...14 14 EB 8355 2 EN...

Page 91: ...EB 8355 2 EN 14 15...

Page 92: ...14 16 EB 8355 2 EN...

Page 93: ...EB 8355 2 EN 14 17...

Page 94: ...14 18 EB 8355 2 EN...

Page 95: ...EB 8355 2 EN 14 19...

Page 96: ...14 20 EB 8355 2 EN...

Page 97: ...EB 8355 2 EN 14 21...

Page 98: ...14 22 EB 8355 2 EN...

Page 99: ...EB 8355 2 EN 14 23...

Page 100: ...14 24 EB 8355 2 EN...

Page 101: ...EB 8355 2 EN 14 25...

Page 102: ...14 26 EB 8355 2 EN...

Page 103: ...EB 8355 2 EN 14 27...

Page 104: ...14 28 EB 8355 2 EN...

Page 109: ......

Page 110: ...2 EB 8355 2 EN...

Page 111: ...EB 8355 2 EN 3...