EB 8355-2 EN

3-1

Design and principle of operation

3

Design and principle of oper

-

ation

Î

See

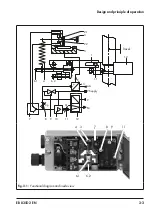

The positioner consists of an electropneumat-

ic converter and a pneumatic unit equipped

with a lever for travel pick-off, a measuring

diaphragm and the pneumatic control system

with nozzle, diaphragm lever (flapper plate)

and booster.

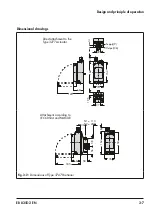

The positioner is designed either for direct

attachment to SAMSON Type 3277 Actua

-

tors or for attachment to actuators according

to NAMUR (

IEC 60534-6

) using an adapter

housing.

The positioner can be additionally equipped

with either inductive limit switches and/or a

solenoid valve or position transmitter.

The control signal, e.g. 4 to 20 mA, issued

by the controller is transmitted to the electro-

pneumatic converter (13) where it is convert-

ed into a proportional pressure signal p

e

.

The positioner operates according to the

force-balance principle. The valve travel, i.e.

the valve position, is transmitted to the pick-

up lever (1) over the pin (1.1) and deter-

mines the force of the range spring (4). This

force is compared to the positioning force

generated by the pressure p

e

at the measur-

ing diaphragm (5).

If either the control signal or the valve posi-

tion changes, the diaphragm lever (3)

moves, altering the distance to the nozzle

(2.1 or 2.2), depending on the adjusted di-

rection of action of the positioner.

The supply air is supplied to the booster (10)

and the pressure regulator (9).

The controlled supply air flows through the

X

p

restriction (8) and the nozzle (2.1, 2.2)

and hits the diaphragm lever (flapper plate).

Any change in the set point or the valve po-

sition causes the pressure to change up-

stream or downstream of the booster.

The air controlled by the booster (signal

pressure p

st

) flows through the volume restric

-

tion (11) to the pneumatic actuator, causing

the plug stem to move to a position corre-

sponding to the set point.

The adjustable X

p

restriction (8) and volume

restriction (11) are used to optimize the posi

-

tioner control loop.

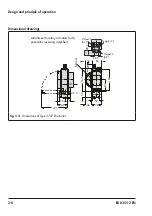

The pick-up lever (1) and the range spring

(4) must be selected to match the rated valve

travel and the nominal span of the set point.

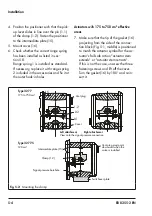

Positioner with inductive limit switches

In this version, the rotary shaft of the

positioner carries two adjustable tags which

actuate the built-in proximity switches.

Positioner with solenoid valve

When the positioner is equipped with a sole-

noid valve, the valve can be moved to the

fail-safe position, regardless of the position-

er's output signal. If a control signal corre-

sponding to the binary signal '0' (OFF) is

applied to the input, the signal pressure p

st

is

shut off and the actuator is vented. The actu-

ator springs move the valve to its fail-safe

position.

When a control signal corresponding to the

binary signal '1' (ON) is applied to the in-

put, the signal pressure p

st

is applied to the

actuator, allowing the valve to move accord-

Summary of Contents for 3767

Page 10: ...1 6 EB 8355 2 EN...

Page 14: ...2 4 EB 8355 2 EN...

Page 58: ...6 2 EB 8355 2 EN...

Page 60: ...7 2 EB 8355 2 EN...

Page 70: ...10 2 EB 8355 2 EN...

Page 72: ...11 2 EB 8355 2 EN...

Page 74: ...12 2 EB 8355 2 EN...

Page 76: ...13 2 EB 8355 2 EN...

Page 78: ...14 2 EB 8355 2 EN...

Page 79: ...EB 8355 2 EN 14 3...

Page 80: ...14 4 EB 8355 2 EN...

Page 81: ...EB 8355 2 EN 14 5...

Page 88: ...14 12 EB 8355 2 EN...

Page 89: ...EB 8355 2 EN 14 13...

Page 90: ...14 14 EB 8355 2 EN...

Page 91: ...EB 8355 2 EN 14 15...

Page 92: ...14 16 EB 8355 2 EN...

Page 93: ...EB 8355 2 EN 14 17...

Page 94: ...14 18 EB 8355 2 EN...

Page 95: ...EB 8355 2 EN 14 19...

Page 96: ...14 20 EB 8355 2 EN...

Page 97: ...EB 8355 2 EN 14 21...

Page 98: ...14 22 EB 8355 2 EN...

Page 99: ...EB 8355 2 EN 14 23...

Page 100: ...14 24 EB 8355 2 EN...

Page 101: ...EB 8355 2 EN 14 25...

Page 102: ...14 26 EB 8355 2 EN...

Page 103: ...EB 8355 2 EN 14 27...

Page 104: ...14 28 EB 8355 2 EN...

Page 109: ......

Page 110: ...2 EB 8355 2 EN...

Page 111: ...EB 8355 2 EN 3...