EB 8052-E EN

9-25

Servicing and conversion

17. Loosely screw lock nut (10) and stem

connector nut (9) onto the plug stem

(5.1).

Valve version with anti-rotation fixture

8. Continue as described in steps 8 to 16 of

the previously described procedure

‘Valve version without anti-rotation fix-

ture’ on page 9-24.

9. Apply a thin film of lubricant (114) to the

threads of the stem (9) and screws (303).

Impaired functioning due to incorrectly

applied lubricant.

Î

Do not apply any lubricant to the threads

of the clamps (301) or the plug stem.

10. Position the clamps (301) and stem (9)

on the plug stem according to the

'Mounting dimensions' table in the 'In-

stallation' section (under 'Mounting the

external anti-rotation fixture') and tighten

screws (303) and washers (304) by

hand.

f) Installing the cage and piston

1.

Clean the inside of the valve body (seat-

ing surfaces of the gaskets) and check it

to ensure that it is free from damage.

2.

Insert a new spiral gasket (127) into the

body (1) in the seat bridge area.

3. Place seat (4) onto the spiral gasket

(127) in the body (1).

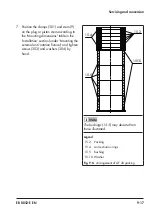

4. Guide cage (124) into the body (1) and

position it onto the seat (4).

5. Insert piston (5) together with the piston

stem (5.1) through the cage (124) verti-

cally into the valve body (1) and position

it on the seat (4).

6. Apply a suitable lubricant (113) to the

piston stem (5.1).

7. Insert a new gasket (45) onto the cylin-

der (63). Make sure the gasket is proper-

ly aligned (see Fig. 9-7).

8. Place cylinder (63) together with the gas-

ket (45) over the piston stem (5.1) onto

the cage (124).

9.

Insert a new spiral gasket (126) onto the

cylinder (63).

10.

Insert a new spiral gasket (17) into the

body (1).

Valve version without anti-rotation fixture

11.

Standard and LLF 20 packing:

apply a

suitable lubricant (113) to all the packing

parts.

HT packing:

do not use any lubricant.

12.

Place the valve bonnet (2) over the piston

stem (5.1) onto the body (1). Make sure

the valve bonnet (2) is properly aligned

(see Fig. 9-8).

13. Press piston (5) firmly into the seat (4),

while fastening down the valve bonnet

(2) with the body nuts (14). Tighten the

body nuts (14) gradually in a crisscross

pattern. Observe tightening torques.

14. Carefully slide the packing parts over the

piston stem (5.1) into the packing cham-

ber using a suitable tool. Make sure to

observe the proper order (see Fig. 9-4,

Fig. 9-5 or Fig. 9-6).

NOTICE

!

Summary of Contents for 3251-E

Page 6: ...Contents EB 8052 E EN ...

Page 34: ...4 6 EB 8052 E EN ...

Page 86: ...9 28 EB 8052 E EN Servicing and conversion ...

Page 92: ...12 2 EB 8052 E EN ...

Page 94: ...13 2 EB 8052 E EN ...

Page 96: ...14 2 EB 8052 E EN ...

Page 100: ...15 4 EB 8052 E EN ...

Page 101: ......