9-16

EB 8052-E EN

Servicing and conversion

13. Insert the plug/piston (5) together with

the plug/piston stem (5.1) vertically into

the valve body (1) and position it in the

seat (4) in the closed position.

Version with V-port plug:

align the plug

(5), making sure that the largest

V-shaped port of the V-port plug faces

toward the valve outlet. See information

under 'Mounting the actuator onto the

valve' in the 'Installation' section.

14. Insert a new spiral gasket (17) onto the

valve body (1).

15. Place the valve bonnet (2) over the plug

or piston stem (5.1) onto the body (1).

16. Firmly press the plug or piston (5) into

the seat (4), while fastening down the

valve bonnet (2) with the body nuts (14).

Tighten the body nuts (14) gradually in a

crisscross pattern. Observe tightening

torques.

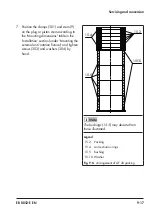

17. Carefully slide the packing parts over the

plug or piston stem (5.1) into the packing

chamber using a suitable tool. Make sure

to observe the proper order (see

Fig. 9-6).

18. Insert packing follower (8).

19.

Place yoke (60) on the valve bonnet (2)

and fasten using the castellated nut (92).

20.

Place packing gland (162) over the studs

(164) on the valve body (2) onto the

packing follower (8).

21.

Screw the two spring loading assemblies

(163) onto the studs (164) and guide

them through the holes on the packing

gland.

22.

Adjust the packing (see information un-

der 'Adjusting the packing' in the 'Instal-

lation' section > 'Testing the installed

valve' > 'Leak test').

23. Loosely thread lock nut (10) and stem

connector nut (9) onto the plug or piston

stem (5.1).

Valve version with anti-rotation fixture

1.

Undo the body nuts (14) gradually in a

crisscross pattern.

2.

Ensure that the clamps (301) are still fas-

tened tight to the plug or piston stem

(5.1).

3. Lift the valve bonnet (2) including yoke

(60), plug/piston (5) and plug/piston

stem (5.1) upwards off the body (1) and

set it aside.

4. Undo the screws (303) and remove the

clamps (301) of the anti-rotation fixture.

Set aside clamps (301), screws (303),

washers (304) and stem (9).

5. Continue as described in steps 5 to 22 of

the previously described procedure

‘Valve version without anti-rotation fix-

ture’ under b) on page 9-15.

6. Apply a thin film of lubricant (114) to the

screws (303).

Impaired functioning due to incorrectly

applied lubricant.

Î

Do not apply any lubricant to the threads

of the clamps (301), stem (9) or plug/

piston stem.

NOTICE

!

Summary of Contents for 3251-E

Page 6: ...Contents EB 8052 E EN ...

Page 34: ...4 6 EB 8052 E EN ...

Page 86: ...9 28 EB 8052 E EN Servicing and conversion ...

Page 92: ...12 2 EB 8052 E EN ...

Page 94: ...13 2 EB 8052 E EN ...

Page 96: ...14 2 EB 8052 E EN ...

Page 100: ...15 4 EB 8052 E EN ...

Page 101: ......