EB 8052-E EN

9-21

Servicing and conversion

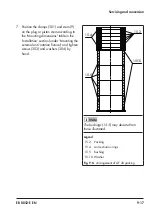

element (63) and flow divider (62) from

the body (1).

14. Undo the seat ring (221) using a special

tool (

u

AB 0100) and remove it from the

body (1).

It may be necessary to first unscrew a

few studs (13) from the body (1) before

the tool can be positioned properly.

15. Remove seat (4) and spiral gasket (127)

from the body (1).

c) Removing the cage and

piston

Standard and HT packing

1.

Loosen threaded bushing (8).

2.

Undo the body nuts (14) gradually in a

crisscross pattern.

3.

Valve versions without anti-rotation fix

-

ture:

ensure that the stem connector nut

(9) is still fastened tight to the piston stem

(5.1).

Valve versions with anti-rotation fixture:

ensure that the clamps (301) are still fas-

tened tight to the piston stem (5.1).

4. Lift the valve bonnet (2) including yoke

(60), piston (5) and piston stem (5.1) up-

wards off the body (1) and set it aside.

5.

Valve versions without anti-rotation fix

-

ture:

unscrew the stem connector nut (9)

and lock nut (10) from the piston stem

(5.1).

Valve versions with anti-rotation fixture:

undo the screws (303) and remove the

clamps (301) of the anti-rotation fixture.

Set aside clamps (301), screws (303),

washers (304) and stem (9).

6. Unscrew castellated nut (92) and lift the

yoke (60) off the valve bonnet (2).

7. Unscrew the threaded bushing (8).

8. Pull piston stem (5.1) out of the valve

bonnet (2).

9.

Pull the entire packing out of the packing

chamber using a suitable tool.

10.

Clean the packing chamber thoroughly.

11.

Remove spiral gaskets (17, 126) from the

body (1) or cylinder (63) and valve bon-

net (2).

12.

Remove cylinder (63) with gasket (45)

and cage (124) from the body (1). For

versions ≥NPS 6, special lifting equip-

ment is available from SAMSON

(

u

13. Remove seat (4) and spiral gasket (127)

from the body (1).

LLF 20 packing

1.

Undo the body nuts (14) gradually in a

crisscross pattern.

2.

Valve versions without anti-rotation fix

-

ture:

ensure that the stem connector nut

(9) is still fastened tight to the piston stem

(5.1).

Valve versions with anti-rotation fixture:

ensure that the clamps (301) are still fas-

tened tight to the piston stem (5.1).

3. Lift the valve bonnet (2) including yoke

(60), piston (5) and piston stem (5.1) up-

wards off the body (1) and set it aside.

Summary of Contents for 3251-E

Page 6: ...Contents EB 8052 E EN ...

Page 34: ...4 6 EB 8052 E EN ...

Page 86: ...9 28 EB 8052 E EN Servicing and conversion ...

Page 92: ...12 2 EB 8052 E EN ...

Page 94: ...13 2 EB 8052 E EN ...

Page 96: ...14 2 EB 8052 E EN ...

Page 100: ...15 4 EB 8052 E EN ...

Page 101: ......