5-18

EB 8052-E EN

Installation

5.1

8

164

163.1

163.2

162

2

92

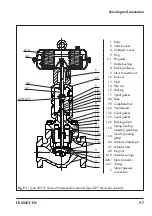

Fig. 5-11:

Packing must be replaced

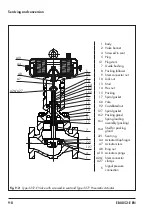

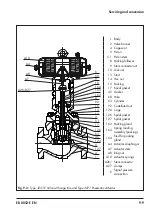

Legend for Fig. 5-8 to Fig. 5-11

2

Valve bonnet

5.1

Plug or piston stem

8

Guide bushing

92

Castellated nut

162

Packing gland

163

Spring loading assembly

163.1 Guide bolt

163.2 Belleville washers

164

Stud for packing gland

5.4.2

Travel motion

The movement of the actuator stem must be

linear and smooth.

Î

Apply the maximum and minimum con-

trol signals to check the end positions of

the valve while observing the movement

of the actuator stem.

Î

Check the travel reading at the travel in-

dicator scale.

5.4.3 Fail-safe position

Î

Shut off the signal pressure line.

Î

Check whether the valve moves to the

fail-safe position (see the 'Design and

principle of operation' section).

5.4.4

Pressure test

The plant operator is responsible for per-

forming the pressure test.

Our after-sales service can support you to

plan and perform a pressure test for your

plant.

During the pressure test, make sure the fol-

lowing conditions are met:

− Retract the plug stem to open the valve.

− Observe the maximum permissible pres-

sure for both the valve and plant.

Tip

Summary of Contents for 3251-E

Page 6: ...Contents EB 8052 E EN ...

Page 34: ...4 6 EB 8052 E EN ...

Page 86: ...9 28 EB 8052 E EN Servicing and conversion ...

Page 92: ...12 2 EB 8052 E EN ...

Page 94: ...13 2 EB 8052 E EN ...

Page 96: ...14 2 EB 8052 E EN ...

Page 100: ...15 4 EB 8052 E EN ...

Page 101: ......