VERS. 2017.06.12

CM 401_MAN_EN

10

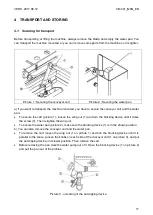

The jig-welded, reinforced and all-steel construction feet ensures perfect stability. Precision springs

allow the feet to be folded up. Handles can be used for the transport of the machine when the feet are

folded up, and for locking the feet when the machine is standing on its feet.

Frame (2)

Built in aluminium profile, the frame is light and resistant.

Cutting head (3)

Jig-welded steel console. Console supports the electric motor and the blade guard. The balancing of

the cutting head is achieved using a heavy-duty spring. A depth-locking device fixed to cutting head

and frame enables the operator to set the cutting head to desired or to maximum cutting depth.

Blade guard (4)

Jig-welded steel construction with 400mm-diameter blade capacity, which offers maximum operator

protection and increased visibility of the work piece.

Incorporated in the blade guard is a shaft vent cover, which can be easily hinged opened. This allows

easy access to shaft for inspection and blade replacement when motor is switched off, while fully

protecting the blade when in operation.

Down feed and cutting depth adjustment (5)

The spring-loaded cutting head, activated by hand with the grip on the blade guard ensures smooth

lowering of the cutting head for shock-free penetration of the work piece and improved control of the

cutting pressure.

Conveyor cart (6)

Large, heavy-duty conveyor cart fitted with water flow-control vents, mounted on 4 rollers to give

maximum stability and smooth movement. The conveyor cart is equipped with graduated scale on the

backstop and with a guide-a-cut device.

Water cooling system (7)

The coolant system comprises:

A powerful, submersible electric water pump.

Plastic suction pipe delivering the water from the water pan to the cutting head.

A removable large capacity aluminium water pan supplied with drain plug.

A water-tap, fitted to the blade guard, permitting controlled water flow.

Two water nozzles located inside the blade guard ensure adequate flow of water to both sides of

the cutting blade.

A water curtain, fixed to head axle restricts water spray and minimises water loss.

Electrical Motor (8)

Summary of Contents for Norton Clipper CM 401 Series

Page 1: ...CM 401 OPERATING INSTRUCTIONS Translation of the original instructions...

Page 2: ...VERS 2017 06 12 CM 401_MAN_EN 2...

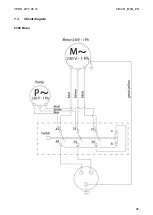

Page 25: ...VERS 2017 06 12 CM 401_MAN_EN 25 7 3 Circuit diagram 230V Motor...

Page 26: ...VERS 2017 06 12 CM 401_MAN_EN 26 115V Motor...

Page 27: ...VERS 2017 06 12 CM 401_MAN_EN 27 400V Motor CM 401 3kW 4 1 A...