15

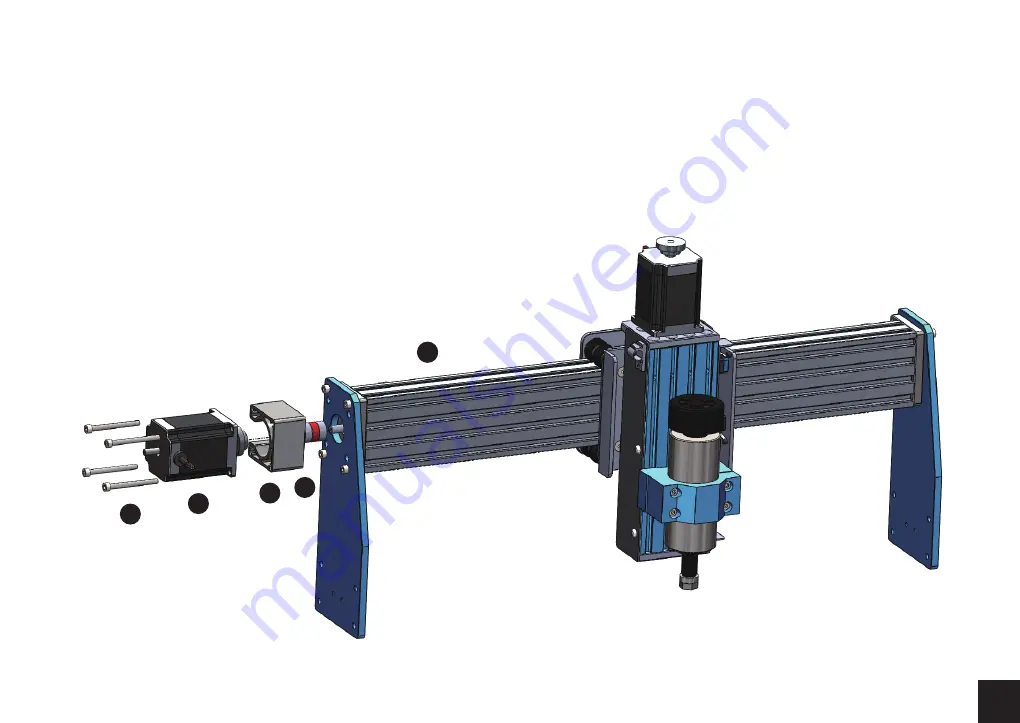

Step 1:

Install the flexible coupler to the X-Axis Leadscrew.

Be sure to loosen the grub screws to ensure the shaft full

seats inside.

Step 2:

Just like the Base preparation. Prep your Stepper

Motor Mount + NEMA 23 Motor and 4 socket cap screws

and remember to position the mount with the opening

facing towards the rear of the gantry.

1

7

35

Step 3:

Mount the assembly to the X-Axis. Tighten the

grub screws on the coupler. Manually twist the wheel

on the Stepper Motor to verify smooth movement of the

Gantry on the X-Axis.

32

6

Summary of Contents for Genmitsu PROVerXL 4030

Page 1: ...V1 0 Aug 2020 USER MANUAL Genmitsu PROVerXL 4030 CNC Router...

Page 14: ...13 29 5 30 12 2...

Page 18: ...17 28 9...

Page 20: ...19 36 37 29...

Page 22: ...21 11 28 28 27 8 33...

Page 24: ...23 10 10 34 37 36 29 11 Congratulations Now your PROVerXL machine body is fully assembled...

Page 36: ...35 Step 2 Probe commands filled in Grblcontrol Candle Fill the Commands here...