Chapter 3: Wiring

Firmware – S1043

Revision: 2 (9/98)

40

© Saftronics, Inc.

3.5.2

Control Circuit Terminal Functions

The functions of the control circuit terminals are shown in

Table 3.9

. Use the appropriate terminals for the correct

purposes.

Table 3.9

Control Circuit Terminals

Type

No.

Signal Name

Function

Signal Level

1

Forward run/stop command

Forward run when CLOSED; stopped when OPEN.

2

Reverse run/stop command

Reverse run when CLOSED; stopped when OPEN.

3

External fault input

Fault when CLOSED;

normal when OPEN

4

Fault Reset

Reset when CLOSED.

5

Multi-step speed reference 1

(Master/auxiliary switch)

Auxiliary frequency

reference when

CLOSED.

6

Multi-step speed reference 2

Multi-step Setting 2

when CLOSED.

7

Jog frequency reference

Jog run when CLOSED.

8

External baseblock

Inverter output stopped

when CLOSED.

Multi-function contact inputs

(Command signals can be

selected by Setting H1-01 to

H1-06.)

Sequence

input

signals

11

Sequence input common

−

24 VDC, 8 mA Photocoupler

isolation

15

15 V power output

15 V power supply for analog reference

15 V

(Maximum current: 20 mA)

33

−

15 V power output

−

15 V power supply for analog references

−

15 V

(Maximum current: 20 mA)

−

10 to 10 V/

−

100% to 100%

0 to 10 V/100%

−

10 to 10 V (20 k

Ω

),

0 to 10 V (20 k

Ω

)

13

Master speed frequence

reference

4 to 20 mA/100%,

−

10 to

+

10 V/

−

100% to 100%

0 to

+

10 V/100%

4 to 20 mA (250

Ω

)

16

Multi-function analog input

−

10 to 10 V/

−

100% to

100%

0 to 10 V/100%

Auxiliary analog input (H3-05)

−

10 to 10 V (20 k

Ω

),

0 to 10 V (20 k

Ω

)

17

Control common

−

−

Analog

input

signals

12

Shield wire, optional ground

line connection point

−

−

9

10

Running signal (1 NO contact)

Operating when CLOSED

25

Zero Speed detection

Zero level (b2-01) or below

when CLOSED

Dry contacts

Contact capacity:

1 A maximum at 250 VAC

1 A maximum at 30 VDC

26

Speed agree detection

Within

±

2 Hz of set

frequency when CLOSED

Multi-function outputs

27

Open-collector output

common

−

Open-collector output

50 mA maximum at 48 V*

18

19

Sequence

output

signals

20

Fault output signal (SPDT)

Fault when CLOSED across 18 and 20

Fault when OPEN across 19 and 20

Dry contacts

Contact capacity:

1 A maximum at 250 VAC

1 A maximum at 30 VDC

21

Frequency output

0 to 10 V/100% frequency

Multi-function analog

monitor 1

(H4-01, H4-02)

22

Common

−

Analog

output

signals

23

Current monitor

5 V/Inverter’s rated current

Multi-function analog

monitor 2

(H4-04m H4-05)

0 to

±

10 V maximum

±

5%

2 mA maximum

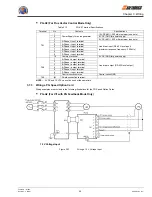

*

When driving an inductive load, such as a relay coil, always insert a flywheel diode as shown in

Figure 3.18.

Figure 3.18

Flywheel Diode Connection