Chapter 1: Introduction

Firmware – S1043

Revision: 2 (9/98)

3

© Saftronics, Inc.

1.1.2

Outline of Control Methods

The VG5 uses four control methods:

•

Open-Loop Vector Control (factory setting)

•

Flux Vector Control

•

V/f Control without PG

•

V/f Control with PG Feedback

Note:

PG stands for pulse generator (encoder).

Vector Control is a method for removing interference with magnetic flux and torque, and controlling torque according to

references.

Current Vector Control independently controls magnetic flux current and torque current by simultaneously controlling the

motor primary current and phases. This ensures smooth rotation, high torque, and accurate speed/Torque Control at low

speeds.

Vector Control can be replaced by the conventional V/f Control system. If the motor constants required for Vector Control

are not known, the motor constants can be automatically set with Auto-Tuning.

The control methods are effective for the following applications:

•

Open-Loop Vector Control:

General variable-speed drive.

•

Flux Vector Control:

Simple servo-drive, high-precision speed control/Torque Control.

•

V/f Control without PG:

Conventional Inverter control mode. Used for multi-drive operation (connecting

multiple motors to one Inverter).

•

V/f Control with PG Feedback:

Simple speed feedback control. (For applications with the PG connected to the

machine shaft rather than the motor shaft.)

The control characteristics for each mode are shown in

Table 1.2

.

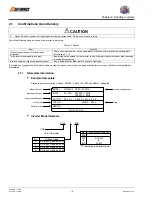

Table 1.2 Control Method Characteristics

Vector Control

V/f Control

Characteristic

Open-Loop

Flux Vector

Without PG

With PG Feedback

Speed Control Range

1:100

1:1000

1:40

1:40

Speed Control

Precision

±0.2 %

±0.02 %

±2 to 3 %

±0.03 %

Initial Drive

150% at 1 Hz

150% at 0 r/min

150% at 3 Hz

1.1.3

Functions

§

Auto-Tuning

Auto-Tuning is effective for Vector Control. It solves problems in applicable motor restrictions and difficult constant

settings. The motor constants are automatically set by entering a value from the motor’s rating nameplate.

Auto-Tuning allows Flux Vector Control to operate accurately with virtually any normal AC induction motor,

regardless of the supplier.

§

Torque Control

Torque Control is effective for flux vector control with PG. Torque in controlled by taking multi-function analog input

signals as torque references. Torque Control accuracy is ±5%. Switching is possible between Torque Control and

speed control.

§

V/f Patter Settings

V/f pattern settings are effective for V/f Control. Select V/f pattern according to the application from among the 15

preset V/f patterns. Custom V/f patterns can also be set.

§

Frequency References

The following five types of frequency references can be used to control the output frequency of the Inverter:

•

Numeric input from the Digital Operator

•

Voltage input within a range from 0 to 10 V

•

Voltage input within a range from 0 to ±10 V (With negative voltages, rotation is in the opposite direction from

the run command.)

•

Current input within the range from 4 to 20 mA

•

Input from Output Card