16

ADJUSTMENTS

—

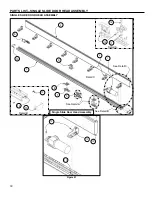

DOOR/BULB SEAL ADJUSTMENT

NOTE: The head assembly trolley track is arranged

to pull the door panel up and away from the

bulb seal as the door opens, so the offset of

the swivel hanger with respect to the bulb

seal side of the door panel will be less at the

leading edge swivel hanger than at the

trailing edge swivel hanger.

Top/Head-Door Bulb Seal Adjustment

1. To adjust the top bulb seal/door panel alignment,

move the door panel(s) to the fully closed

position.

2. Turn off the power to the door.

The disconnect must be in the OFF position

and properly locked and tagged before

performing the following procedure.

3. Check and confirm that each insulated door

panel is level along its top edge and aligns/mates

with the top bulb seal. If adjustment is necessary

do so according to the “DOOR PANEL

ALIGNMENT AND ADJUSTMENT

” procedure on

page 14.

4. Arrange the door panel(s) so they may be

checked as follows:

a. On bi-parting doors, manually move the door

panel which is not being checked to the fully

open position. Leave the door panel to be

checked in the closed position.

b. On single slider doors, leave the door panel in

the closed position.

Figure 38

5. From the back side of the door panel (left or right

side of the door), check the horizontal and

vertical seal between the door panel and bulb

seal on the door opening top jamb. The door top

bulb seal must fit tight against the back of each

door panel along the complete door panel width.

The door panel should compress the bulb seal

¼-½ inch. Check this at the leading, trailing, and

vertical top door panel edges. Bi-parting door

panel centers must be aligned. (See Figure 38)

6. If any door seal adjustment is required on the top

of the door, loosen the screws securing the door

panel to the swivel hanger plate at the top of the

door opening. Then move the door panel until it

mates correctly against the full length of the bulb

seals along the back of the door panel(s).

Tighten the screws to 15 ft-lbs using a figure 8

pattern, locking the door panels in place.

7. Do this for all the door panels.

8. Restore power to the door and return to service.

It is critical the door is not compressed against

the bulb seal too tight. Too much compression

will cause the door motor to stall out and

premature wearing of the bulb seals.

Door Retention/Stay Roller-Door Bulb Seal

Adjustment

Once the top seal has been properly adjusted the

lower floor seal should be adjusted. Adjust the

bottom and vertical side seals in the same manner as

adjusting the top/head-door bulb seal.

1. To adjust the bottom bulb seal/door panel

alignment, move the door panel(s) to the fully

closed position.

2. Turn off the power to the door.

The disconnect must be in the OFF position

and properly locked and tagged before

performing the following procedure.

3. From the back side of the door panel (left or right

side of the door), check the vertical seal between

the door panel and the bulb seal on the door

jamb of the door opening. The doors bulb seal

must fit tight against the back of each door panel

along the complete door panel height. The door

panel should compress the bulb seal anywhere

from ¼-½ inch. Check this at the trailing vertical

door panel edge when the door panel is in the

fully closed position.

Bulb seal/door

panel mating

seal

Swivel hanger

fastening bolts

Adjust door

panel in swivel

hanger

Stay roller

door retainer

Adjust stay roller

to compress

door panel