17

ADJUSTMENTS

—DOOR PANEL ALIGNMENT AND ADJUSTMENT

4. If any door seal adjustment is required on the

bottom half of the door, loosen the screws

securing the door panel stay roller to the floor.

Then move the stay roller until the correct mate

against the full length of the bulb seal along the

back of the door panel(s) is achieved. Confirm

stay rollers do not encroach the opening and are

directly in front of the bulb seal. Tighten the stay

roller fasteners, locking them in place on the

floor. The F80 Standard Stay Roller may also be

adjusted by loosening the bottom ¾-10 hex nut

and moving the wheel on the bracket. (See

Figures 38, 15, and 16)

5. Do this for all the door panels.

6. Turn on the power to the door.

7. With all seals adjusted and secured, cycle the

door open and closed several times to test the

seals. Then fully close the door and verify that

the adjustable seals around the door opening

have remained in place and fit properly against

the back of the door. On Bi-Parting doors also

verify that both door panel leading edge seals

mate and seal properly. Make any necessary

adjustments.

DOOR LEADING EDGE SEAL ADJUSTMENT BI-

PARTING DOORS

On Bi-Parting doors the door panel leading edge seal

creates the seal between the door panels when fully

closed.

If there isn’t a proper seal first check that the

leading edge seals are in good condition, properly

centered, and aligned on each door panel. If not, pull

off and adjust as required. Next confirm that the

panels are level and mate properly with each other to

form a proper seal. Adjustment may also be required

if the door panels are not in proper alignment. If the

door panels have been properly aligned for level and

don’t provide a proper seal they are likely not

properly aligned with each other’s center plane offset

from the door opening face and head assembly. The

door panels must be level and aligned per

“DOOR

PANEL ALIGNMENT AND ADJUSTMENT” on page

14 and

“Top/Head-Door Bulb Seal Adjustment” on

page 16.

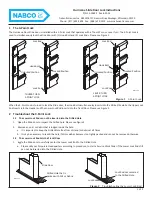

DOOR PANEL FLOOR SWEEP SEAL

ADJUSTMENT

The door panel floor sweep seal is located at the

bottom of each door panel and provides the seal for

that portion of the door with the floor. Alignment is

controlled by the mounting position of the sweep

assembly on the door panel and the doors swivel

hangers.

In the event that the seal is either too tight or too

loose between the door panel and the floor, the door

panel itself can’t be raised or lowered, or the floor

sweep seal needs to be adjusted for some other

reason,

the door panel’s floor sweep seal itself can

be adjusted on the door panel. The seal is attached

with industrial hook and loop for easy adjustment.

1. To adjust the door panel(s) floor sweep seal,

move the door panel(s) to the fully closed

position.

2. Turn off the power to the door.

The disconnect must be in the OFF position

and properly locked and tagged before

performing the following procedure.

3. Check and confirm that each insulated door

panel is level along its top edge and aligns/mates

properly with the bulb seal. On Bi-Parting doors

confirm that the leading edges of both door

panels are properly mated with each other. If

adjustment is necessary do so according to the

“DOOR PANEL ALIGNMENT AND

ADJUSTMENT” procedure on page 14.

4. Remove each floor sweep seal by pulling apart at

the seam. Adjust the seal for proper fit and then

firmly attach the hook and loop back together.

(See Figure 39)

Figure 39

5. Do this for all the door panel floor sweep seals.

6. Turn on the power to the door.

7. With all seals adjusted and secured, cycle the

door open and closed several times to test the

seals. Then fully close the door and verify that

the floor sweep seals around the door panel

have remained in place and seal properly against

the floor. Make any necessary adjustments.

DOOR PANEL FLOOR SWEEP SEAL