8

INSTALLATION—HEAD ASSEMBLY

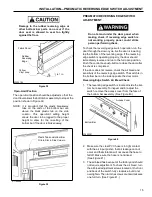

Also, some oversized doors (with or with- out

pullouts) require a steel spacer between both side

columns and the head assembly. If your door is

oversized, locate two 9-in. x 1 3/4-in. steel spacers

shipped in the small parts carton. (The spacers are

further identified by a hole at each end.)

If spacers were included in the small parts

carton but the door does not include

pullouts, four 1/2-13 x 2-in. serrated-flange

hex

screws were substituted for the slightly

shorte4 1/2-13 x 1 1/4-in. screws mentioned

above in step 1. The 2-in. screws were

shipped in the small parts carton.

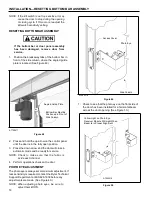

2. Remove the head/fabric roll assembly from the

shipping crate.

Before lifting the roll assembly, secure

both side columns to the building wall.

Secure the roll assembly to the forklift

before lifting. Failure to secure the side

columns or the roll assembly can result in

serious injury and property damage. DO

NOT remove the forklift until the assembly

is secured to both side columns.

IMPORTANT: If your door is oversized, two

large spacers were included in

the small parts carton. Failure to

install a spacer between the

motor mounting bracket and

flange bearing assembly could

result in damage to the door.

(See Figure 18 and Figure 19.)

5. Attach the motor mounting bracket to the side

column using two 1/2-13 x 1 1/4-in. serrated-flange

hex screws and nuts (or two 1/2-13 x 2-in. screws

and nuts). Doors with 3 or more windribs will have

spacers for the drive and non-drive side to shim the

drum roll assembly away from the rear spreader.

Failure to install these spacers (if supplied) will

cause the drum roll to jamb against the rear

spreader due to the diameter of the drum roll.

Doors with 2 windribs or less will not have the shim

material. DO NOT tighten the hex nuts at this time.

(See Figure 18.)

Motor Mounting

Bracket

IMPORTANT:

Install spacer between

motor mounting bracket and side

column (if spacer is supplied).

Side Column

Use care when handling the fabric roll to

ensure that the fabric is not torn or dam-

aged. DO NOT remove the shipping bands

holding the fabric to the roll.

IMPORTANT: The fabric and bottom bar, un-roll

from the back of the drum

assembly.

3. Using a forklift, lift the head/fabric roll

assembly in place.

4. Position the head assembly in front of the pair of

holes near the top of each side column. Align the

holes in the motor mounting bracket with the

holes in the side column. (See Figure 18.)

A7500247

Figure 18

Serrated-Flange

Hex Screws and Nuts

(Hex Nuts Only If

Pullouts Were Used

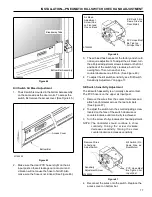

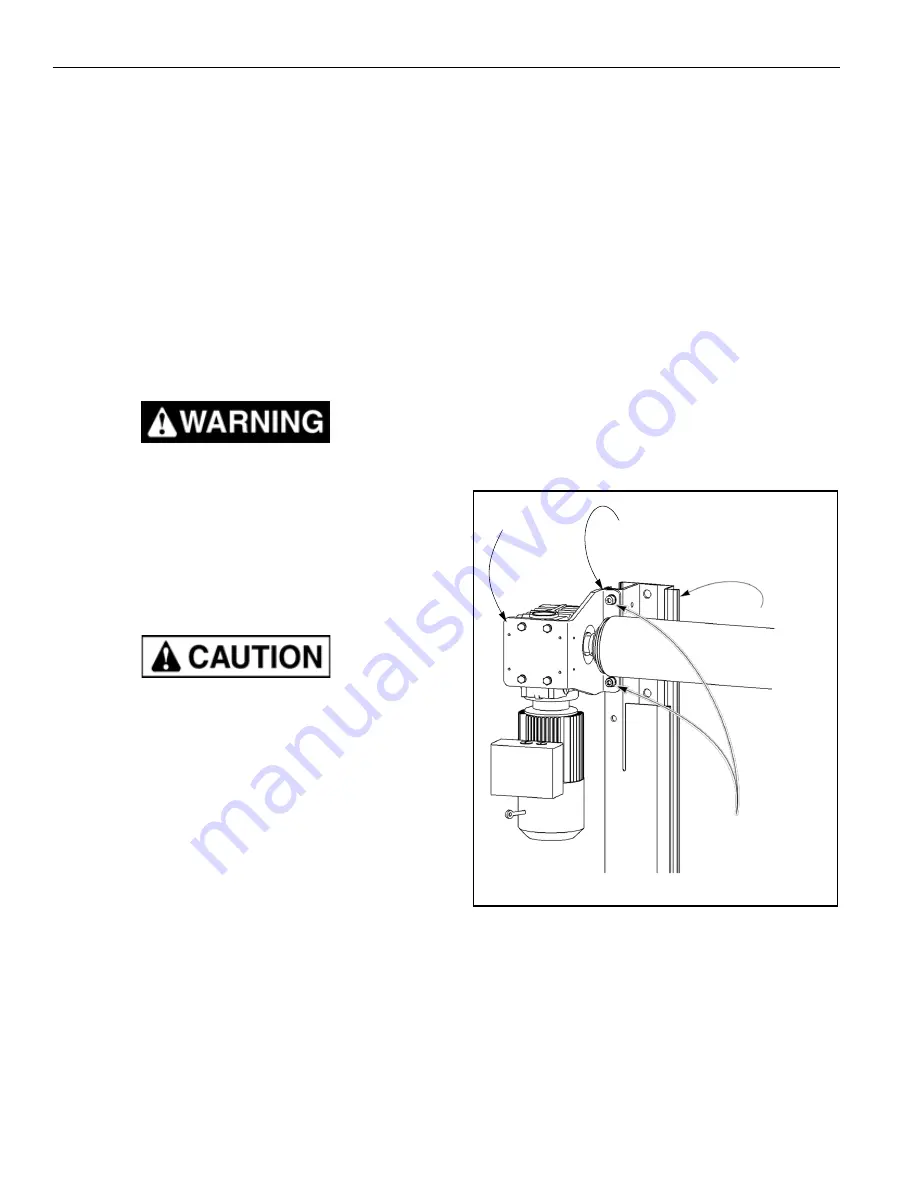

6. Slide the flange bearing assembly over the drum

shaft at the non-drive end of the head/fabric roll

assembly. (See Figure 19.)

IMPORTANT: If your door requires spacers, be

sure to install a spacer between

the flange bearing assembly and

the side column. (See Figure 19.)