4

INSTALLATION—LOCATING CENTERLINE OF DOOR OPENING

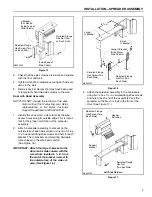

LOCATING CENTERLINE OF DOOR OPENING

NOTE: Accurate measurements are critical for the

proper installation and operation of your

Rytec door. Verify all measurements.

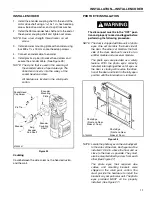

1.

Measure the width of the door opening.

2.

Divide the measurement in half to locate the center-

line. Then mark the centerline along the floor.

(See Figure 7.)

Figure 7

LOCATING SIDE COLUMNS

1.

Locate the layout drawing of the door. It should be

attached to the small parts carton packed inside the

shipping crate. This drawing identifies the produc-

tion width of your door.

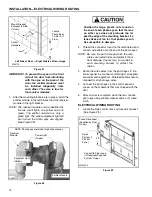

2.

Using the centerline as a reference point, lay out

and mark half of the door’s production width along

the floor. (See Figure 8.)

This door is equipped with a breakaway

bottom bar assembly. To ensure that it

works properly, the width of the door

opening must not be smaller (narrower)

than the production width of the door. If

the width of the opening is narrower than

the width of the door, do not proceed with

the installation. Contact your Rytec repre-

sentative or Rytec Customer Support

Department at 800-628-1909.

Figure 8

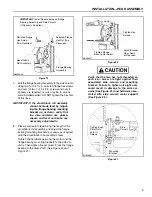

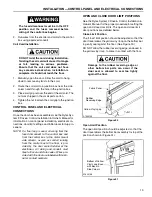

3.

With a carpenter’s square placed against the wall,

mark both sides of the door along the floor. Extend

the line along each edge.

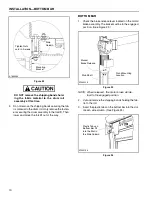

4.

Check the floor for level across the door opening.

The floor must be level within 0.12 in. from side-to-

side. If one side of the opening is higher than the

other, a shim under the side panel will be required.

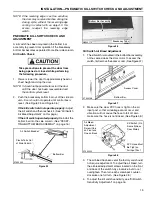

Figure 9 and Figure 10 show two methods that can

be used to ensure level side columns.

NOTE: Contact the Rytec Customer Support

Department if the floor is more than 1 in.

out of level.

Figure 9

A0500001

Centerline of

Opening

Overall Width

of Door Opening

Half Width of

Door Opening

A0500002

Half of Door

Centerline of

Opening

Production

Extend and Mark

Edges of Door Along Floor

Width

A0500003

Line Level

This Dimension Must Be

Equal on Both Sides of

Door Opening

Shim Plate

(If Required)

Summary of Contents for Pharma-Roll

Page 1: ...Pharma Roll Installation Manual Revision January 15 2009 0715009 Rytec Corporation 2007...

Page 2: ......

Page 23: ...NOTES 19...

Page 24: ......