12

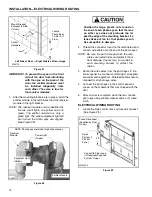

INSTALLATION—ELECTRICAL WIRING ROUTING

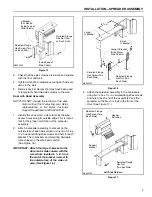

Figure 27

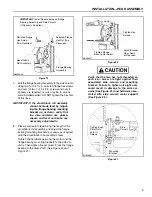

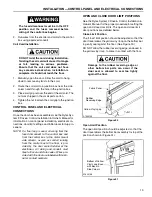

IMPORTANT: To prevent the eyes on the front

side of the door from interfering

with the eyes on the back of the

door, the emitter modules must

be installed diagonally from

each other. The same is true for

the receiver modules.

1.

After the mounting brackets are in place, install the

emitter module in the left bracket and the receiver

module in the right bracket.

NOTE: The receiver module can be identified by

the two small lights, one yellow and one

green. The emitter module has only a

green light. The yellow alignment light will

be lit when the photo eyes are aligned.

(See Figure 28)

Figure 28

Position the large, plastic nuts found on

the end of each photo eye so that the lens

on either eye does not protrude too far

past the edge of the mounting bracket. If a

lens sticks out too far, that photo eye will

be susceptible to damage.

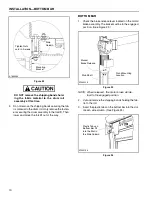

2.

Thread the connector found on the terminated end

of each wire cable onto the end of the photo eyes.

NOTE: Be sure the path through which the wire

cables are routed hides and protects them

from damage. If necessary, run conduit to

each mounting bracket to protect the

cables.

3.

Route the wire cables from the photo eyes to the

control panel in a manner conforming to all applica-

ble codes and regulations. Shielded cable is recom-

mended for all photo eye wires.

4.

Connect the photo eyes to the control panel as

shown on the schematic that was shipped with the

door.

5.

After all work is complete, clean the lens of each

photo eye using window cleaner and a soft, clean

cloth.

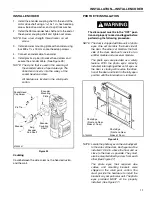

ELECTRICAL WIRING ROUTING

1.

Locate the Rytec control box and fused disconnect.

(See Figure 29.)

Figure 29

Anchor

Locate

Hardware

A750119

Photo Eyes

12–36-in. O

Floor

Mount Bracket

Adjacent to Side

Column

Left Side of Door — Right Side Is a Mirror Image

A6500173

Power Light

(Green)

Alignment Light

(Yellow)

Emitter Module

NOTE: Photo eyes are joined for photo purposes.

Receiver

Module

A7500253

Fused Disconnect

(Supplied by Door

Owner)

Conduit to Floor Loop

(If Required) Supplied

by Door Owner

4 ft.

Rytec

System 3

Control

Panel

Summary of Contents for Pharma-Roll

Page 1: ...Pharma Roll Installation Manual Revision January 15 2009 0715009 Rytec Corporation 2007...

Page 2: ......

Page 23: ...NOTES 19...

Page 24: ......