7

x

Gas burner

FA ROTEX A1 BGe - 02/2014

35

7.3.2 Checking and setting the burner

The burner is configured for a certain type of gas at the factory.

The preset gas type and the designated gas inlet pressure are in-

dicated on the yellow sticker placed on the burner housing.

Testing the burner output using the flue gas analysis unit in the

operating mode "Emission Measurement" (see chapter 15.2)

Ɣ

at "Full Load"

Ɣ

at "Base Load"

Using this operating mode you can activate the parameters set in

the parameter level "Expert Config", "Full Load" (parameter "Fan

Max") and the "Base Load" (parameter "Fan Min"). Within the

permissible limit values (see tab. 7-2 to tab. 7-3), these settings

can be adjusted individually to the respective system require-

ments.

Auxiliary resources

– Flue gas analysis device.

– Pressure meter for measuring gas pressure.

Tests and settings (observe the sequence)

1. Inspect the pre-settings, so that the burner is set to the correct

gas type and the correct gas inlet pressure.

If the test gas indication on the yellow sticker on the burner

housing varies from the test gas associated to the available

gas type or if the stated value deviates from the permissible

gas inlet pressure, the burner must be converted to the local

conditions (see section 7.3.3 to 7.3.6).

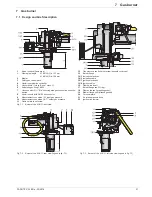

2. Turn the screw in the gas inlet pressure measuring

connection (fig. 7-3, item 9) anticlockwise by half a turn and

push up the measuring hose of the pressure meter.

3. Open the gas stopcock.

4. Measure the gas inlet pressure (idle pressure) and compare

it with the target value (see tab. 12-3). Leave the measuring

instrument connected.

– If the gas inlet pressure (resting pressure) is outside the

set value range: Inform your gas supply company or

check the pressure regulator (for liquid gas).

5. Open the heating valves.

6. Switch on ROTEX A1 with main switch.

7. Switch on the operating mode "Emission Measurement" for

Full Load.

8. Connect up the flue gas analysis unit.

9. Check flow pressure.

– The gas intake flow pressure is not allowed to drop signif-

icantly below the idle pressure less the pressure drop in

the corrugated gas connection hose (up to 5 mbar for

42 kW burner load). If the flow pressure is too low, the

burner output also drops.

10. If the measured flue gas values do not change anymore (for

the soonest

3 min

after the start of the burner), measure the

CO

2

-content and the O

2

-content. Compare the measured

values with the specified setting values (see section 7.3.1).

11. If the CO

2

concentration is outside

±

0.2 % or the O

2

concentration is outside

±

0.3 % of the set target values:

Readjust burner

using the adjusting screw for the gas/air

mixture (fig. 7-3, item 11) :

– Left turn (counter clockwise)

Î

more gas: O

2

↓

, CO

2

↑.

– Right turn (clockwise)

Î

less gas: O

2

↑

, CO

2

↓.

12. Set operating mode "Emission Measurement" to Base Load.

13. If the measured flue gas values do not change anymore (for

the soonest

2 min

after energy change), measure the CO

2

-

content and O

2

-content. Compare the measured values with

the specified setting values (see section 7.3.1).

14. If the CO

2

concentration is outside

±

0.2 % or the O

2

concentration is outside

±

0.3 % of the set target values or

the burner whistles:

Readjust the burner

using the adjusting

screw for the gas pressure controller (fig. 7-3, item 12)

(see section 7.3.6):

– Left turn (counter clockwise)

Î

less gas outlet

pressure: O

2

↑

, CO

2

↓.

– Right turn (clockwise)

Î

more gas outlet

pressure: O

2

↓

, CO

2

↑.

15. Set the operating mode "Emission Measurement" to Full Load

and re-check the combustion values.

– The values adjust according to the specifications (com-

pare step 8)

Î

adjustment procedure is finished.

– The values adjust not according to the specifications

Î

repeat the steps 8-14.

16. Enter all changes to the performance set values on the setting

type plate at the top of the boiler control panel (fig. 3-1,

item 23) and in the operating manual.

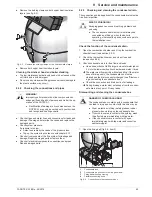

7.3.3 Carrying out the basic setting on the burner.

If the burner does not start, even with the power and gas supply

properly connected and with the flue gas path free, a new burner

basic setting must be carried out see section.

Basic setting

1. Screw in the adjusting screw for the gas/air mixture (fig. 7-3,

item 11) clockwise up to the stop (do not tighten).

2. Open the adjusting screw for the gas/air mixture according to

tab. 7-4 counter clockwise:

*

Liquefied petroleum gas design (F)

3. Restart the burner.

4. If the burner does not start, open the adjusting screw for

gas/air mixture further by

2 more turns

and restart the

burner.

If the burner does not start, even with the power and

gas supply properly connected and with the flue gas

path free, a new burner basic setting must be carried

out (see section 7.3.3).

Gas type

Associated test

gas

Number of rotations

A1 BG 25(F)-e A1 BG 40(F)-e

Natural gas

E/H

G20

8

9

Natural gas

LL/L

G25

10

11

Propane*

G31

9

11

Butane*

G30

7

9

Tab. 7-4 Number of rotations for adjusting the gas/air mixture

After the basic settings of the burner have been carried

out, the burner must be checked and fine adjustment

must be carried out (see section 7.3.7).