Commissioning and operation

Version 2

RES-5008

Page 23

the AUTOCAL function must be carried out again. To do this, the system (heating element, base, body, ...) must

be cooled off completely.

After the first heating and renewed zeroing (AUTOCAL), the heating element is burned in and the change of resist-

ance is stabilised. The heating element can now be used.

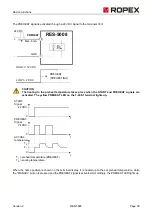

Burn-in process:

It is carried out while the tool is open

1. Carry out AUTOCAL, so that the controller calibrates itself to the cold resistance of the heating element.

2. Heat the heating element to 250 °C, but at least 50 °C above the application-related sealing temperature.

3. Let the system (heating element, base, body, ...) cool down completely until the heating element temperature

is stable.

4. Carry out AUTOCAL again so that the new cold resistance can be measured.

8.3.2

The burn-in effect described here does not need to be considered if the manufacturer pre-treated the

heating element for this purpose. The thermal pre-treatment is described as “burned in” at ROPEX in the

article text

.

Changing the heating element

ROPEX recommends changing the heating element in case of:

• mechanical defects, bending or deformations

• scaled or oxidised heating element ends

• burned-in deposits

• damaged coatings, e.g. copper coating or Teflon-coating

NOTE

If heating elements are used that have not been thermally pre-treated, the machine control

(HMI) must enable the heating elements to be burned in.

WARNING

A damaged or burned out heating element may no longer be used due to irreversible changes

in the material properties. This leads to a malfunction in the regulation.

NOTE

The heating element must be changed in accordance with the manufacturer’s instructions.

WARNING

For changing the heating element, the supply voltage must be disconnected RESISTRON

®

Temperature Controller RES-5008 at all phases.