Industrial 18.1" Flat Panel Monitor

33

Publication 6185-UM001B-EN-P

3.

Route the power wires from your 18-32 VDC power supply and

connect the leads to the DC input terminal block on the monitor as

shown in the following figure. Tighten the screw terminals to ensure

a good connection.

Figure 24

Connecting Power to the Terminal Block

4.

Restore DC power.

To connect DC power to the Versa mount (6185-V ) monitor:

1.

Turn off the main switch or breaker.

2.

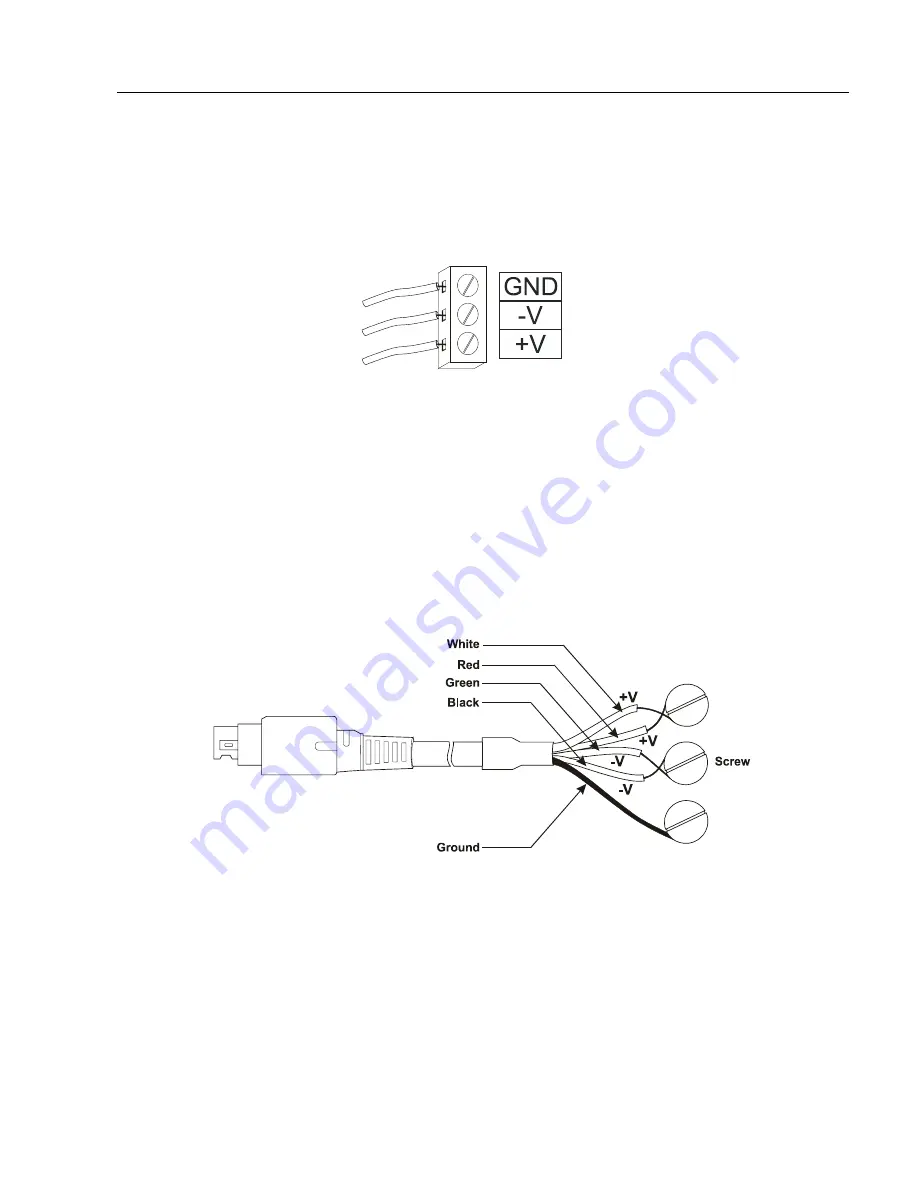

Connect the power cable to the power supply if it is not already

connected. See the figure below.

Figure 25

Connecting Power to the Versa Mount (6185-V)

Note:

To reduce voltage drop from the source, connect both

+V leads to a +12V source and both -V leads to a -12V

source.

3.

Connect the locking DIN connector on the power cable to the

monitor.

4.

Restore DC power.

Summary of Contents for 6185-D

Page 63: ......