MH TH

Pag. 19

REV. 08 11/07

UK

voltage corresponds to the voltage stated on the machine label. The permitted tolerance is

±

10%

of rated voltage. When sizing the differential thermomagnetic switch, take into account the

electrical input values stated on the label.

•

Important note: the thermomagnetic switch must be placed next to the machine so as to be easily

seen and reached by a technician in case of maintenance.

•

The section of the power supply cable must be adequate for the power absorbed by the machine,

which is stated on the relevant label fixed to the machine itself.

•

The law requires that the unit be earthed; therefore, it is necessary to connect it to an efficient

earthing system.

No liability whatsoever can be accepted in the event of failure to comply with this

requirement or if the electrical system to which the machine is connected does not comply with the

regulations in force.

•

For machines with three-phase electrical power, it is necessary to check the rotation direction of

the motor fans. If it does not correspond to the one shown by the arrow on the label placed near

the fans, it is necessary to switch off the machine and invert two phases of the mains; it is then

possible to re-start the machine.

•

A mechanical thermostat set at 40°C must be fitted to the evaporator; this will deactivate the

heaters in case of overheating. The thermostat bulb must be placed in the fin assembly in the

highest position inside the evaporator.

Important note: Scroll compressors compress only in one rotation direction. However, three phase

compressors will rotate in both directions depending upon the phase connections to T, T2 and T3

terminals. Since there is a 50% possibility of connecting them so that they rotate in the reverse

direction, it is very important to check the correct rotation direction. This is checked by monitoring

the drop in suction pressure and the rise in discharge pressure when the compressor is started.

Reverse rotation will produce a sound level that is higher than the one produced by the correct

rotation direction and an electrical input that is higher than that quoted in the catalogue. We advise

you to fit a protection device for inverse phases, which will operate if the phases are not correctly

connected.

6.

TECHNICAL DATA

All MH-TH condensing units are supplied in nitrogen pressure. They are provided with safety

pressure switches with fixe setting and automatic reset on the HBP line, and with adjustable setting

and automatic reset on the LBP line.

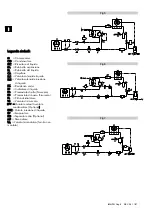

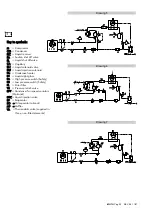

The refrigerating diagram of a condensing unit with air-cooled condensation has been included here

below:

•

Drawing 5: refrigerating diagram with scroll compressor and liquid injection valve (DTC)

•

Drawing 6: refrigerating diagram with scroll compressor and capillary injection

•

Drawing 7: refrigerating diagram with scroll or reciprocating compressor

Important note: Refrigerating diagrams of non-standard units will be supplied separately.

Summary of Contents for MH-HT

Page 2: ...MH TH Pag 2 REV 08 11 07 ...

Page 67: ...MH TH Pag 67 REV 08 11 07 ...

Page 69: ...MH TH Pag 69 REV 08 11 07 ...

Page 70: ...MH TH Pag 70 REV 08 11 07 ...

Page 71: ......