MH TH

Pag. 16

REV. 08 11/07

UK

Drawing. 1

Serial number identification:

•

1

st

and 2

nd

numbers = year of production

•

3

rd

and 4

th

numbers = week number of the year in which the machine was produced

•

5

th

, 6

th

, 7

th

and 8

th

numbers = progressive number

4.

MACHINE DESCRIPTION

MH-TH units are condensing units and split systems with silent housing for commercial refrigeration.

They have been designed following the style of split air conditioning units of which they keep the

main advantages: outside installation, low-noise operation, reduced size.

5.

INSTALLATION

Before installing, it is necessary to make a layout of the refrigerating system; this must include the

following:

a) all components of the refrigerating system ( i.e.: condensing unit, evaporator, thermostatic valve,

electrical panel, piping dimensions, any safety devices, etc.)

b) system location

c) piping location

•

Installation must only be performed by qualified staff with the necessary technical requirements,

according to the country in which the machine is installed.

•

The machine must not be installed in a closed environment where a good air flow is not

guaranteed.

•

Leave enough space around the condensing unit for it to be possible to perform maintenance

operations in safe conditions.

•

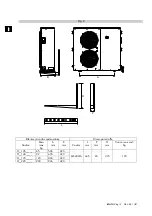

Lift the machine by means of a forklift truck (or other hoisting equipment), using bands or ropes

as shown in Drawing. 2.

•

For information about weight, see the table of general features at the end of this manual.

•

The machine must be fixed to the floor in a vertical position only and by passing screw anchors

(Fischer) through the relevant holes in the unit frame.

5. 1

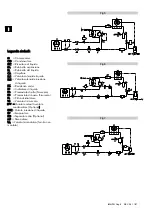

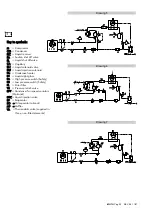

Refrigerating connection

In order to make the connections, suction and liquid line piping with the same diameters as the

connections fitted on the machine must be provided (see the table of general features at the end of

this manual).

These diameters are valid up to a maximum length of 10m. For longer sizes, piping diameters must

be of a correct size to guarantee the proper gas speed.

Pipes must be fixed to the wall on bends and welding points and every 1.5m – 2m on straight

stretches.

Label

Summary of Contents for MH-HT

Page 2: ...MH TH Pag 2 REV 08 11 07 ...

Page 67: ...MH TH Pag 67 REV 08 11 07 ...

Page 69: ...MH TH Pag 69 REV 08 11 07 ...

Page 70: ...MH TH Pag 70 REV 08 11 07 ...

Page 71: ......