13

For more information visit

rimage.com/support

Maintaining the 2450

This section provides maintenance information for the 2450 system,

including the integrated Everest 400 printer.

Important:

For optimum performance, keep the 2450 in a clean, dust-

free environment.

13.1:

Importance of Maintenance

Regular preventative maintenance of your system can help to ensure error-

free recordings and clean printed labels. Maintenance involves cleaning the

system.

Cautionary Information

n

Caution:

To avoid damaging the

2450

during maintenance:

•

•

Never use oils, silicone, or other lubricants on any part of the system.

Use only non-abrasive cleaners to wipe down the surfaces of your

system.

•

Av

oid pouring cleaners directly onto the autoloader. Instead, apply

the cleaner on a clean, lint-free cloth.

Integrated Everest 400 Printer Maintenance

Clean the tacky rollers. Refer to the

Cleaning the Tacky Rollers and Sensors

section on page 1

4

.

•

Sponge swabs

(included in the

Everest cleaning

kit)

•

99% Isopropyl

alcohol

Clean the sensors. Refer to the

Cleaning the Tacky Rollers and Sensors

section on page 1

4

.

•

Sponge swabs

(included in the

Everest

cleaning kit)

•

99% Isopropyl

alcohol

If the print ribbon

is not detected,

the upper or

lower sensor is

not responding, or

the label is off

center

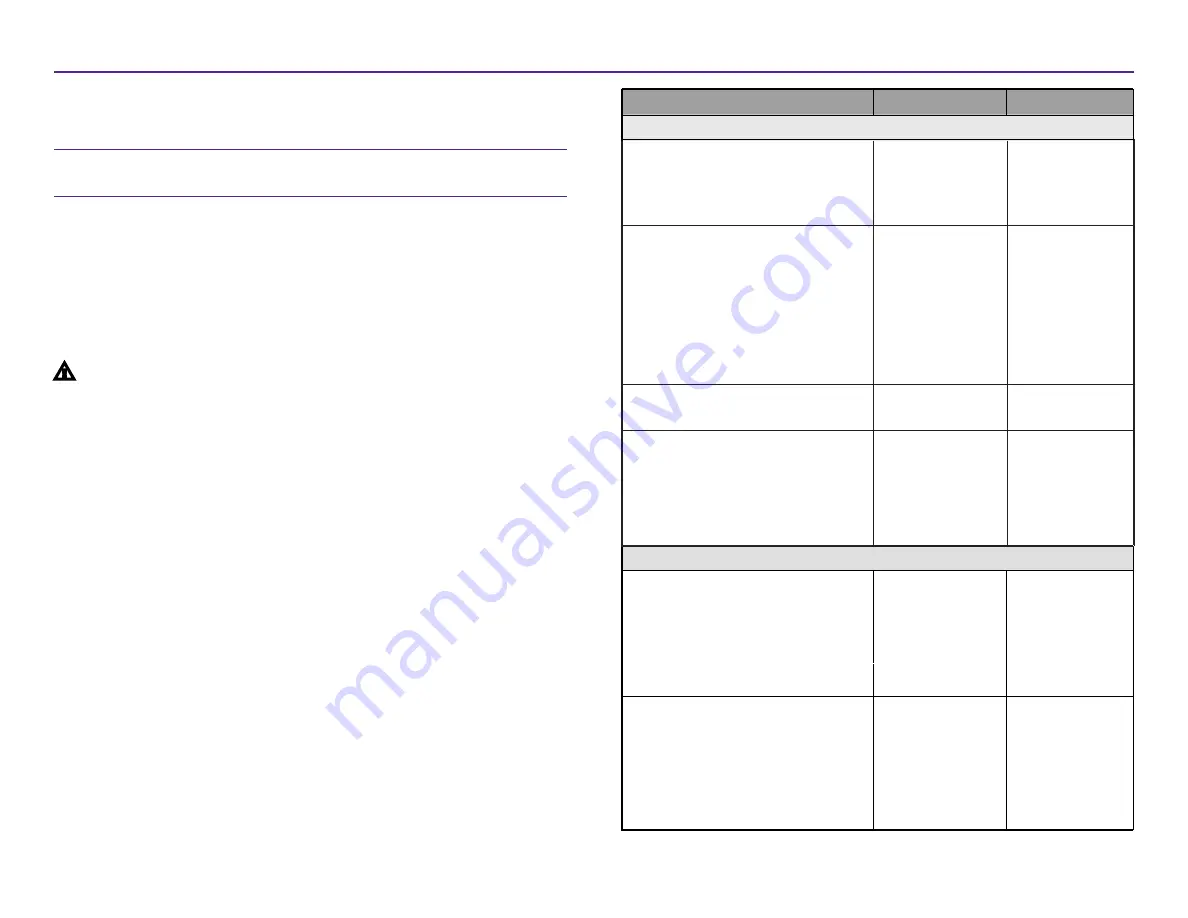

13.2:

Preventative Maintenance Schedule

The following is a table of maintenance tasks, the tool required to

complete them, and their required frequency.

After 2000 discs

or at every ribbon

change

2004849_A

Wipe down the lift arm shaft. Pay close

attention to:

•

The base of the shaft

•

The area just above the lift arm

Lint-free

cloth

Weekly

Wipe down all surfaces of the

autoloader including:

•

Sides and top

•

Door

•

Output bin

•

Carousel

•

Base (remove the carousel first)

•

Top surface on the lift arm

Lint-free

cloth

Non

-

abrasive

,

all-purpose

cleaner

Weekly

Inspect air filter on the side of

the system and replace if necessary.

N/A

Monthly

Inspect the openings at the back of the

autoloader. Remove dust and debris if

necessary.

Remove the carousel and remove dust

and debris from the openings.

Vacuum

Monthly

Task

Tools

Frequency

Autoloader Maintenance