Page 6

8

3.4.4 Lubrication

The INOVAC vacuum pump is a dry running pump and

consequently the only lubrication to the stages is to the

bearing and gear drive areas. This is by means of splash discs

(see picture 7). Depending upon stage size the total oil fill

quantity, including pipelines and storage reservoir is approxi-

mately 1.3 1 l.

Oil is supplied from the external reservoirs to the stages via

the flange at the A-side. Located on the right hand side of drive

side flange (seen from the drive end) are two oil pipes which

feed the B-side. The lower, larger pipe is the oil supply

(pressure free) and the upper pipe is for equalisation.

The oil reservoir should be changed at approximately every

8000 operating hours or at least yearly.

At a misfunction, which can lead to the intrusion of products in

the bearing rooms, is to be explored the oil on his lubrication

property.

All other bearings are sealed for life requiring no maintenance.

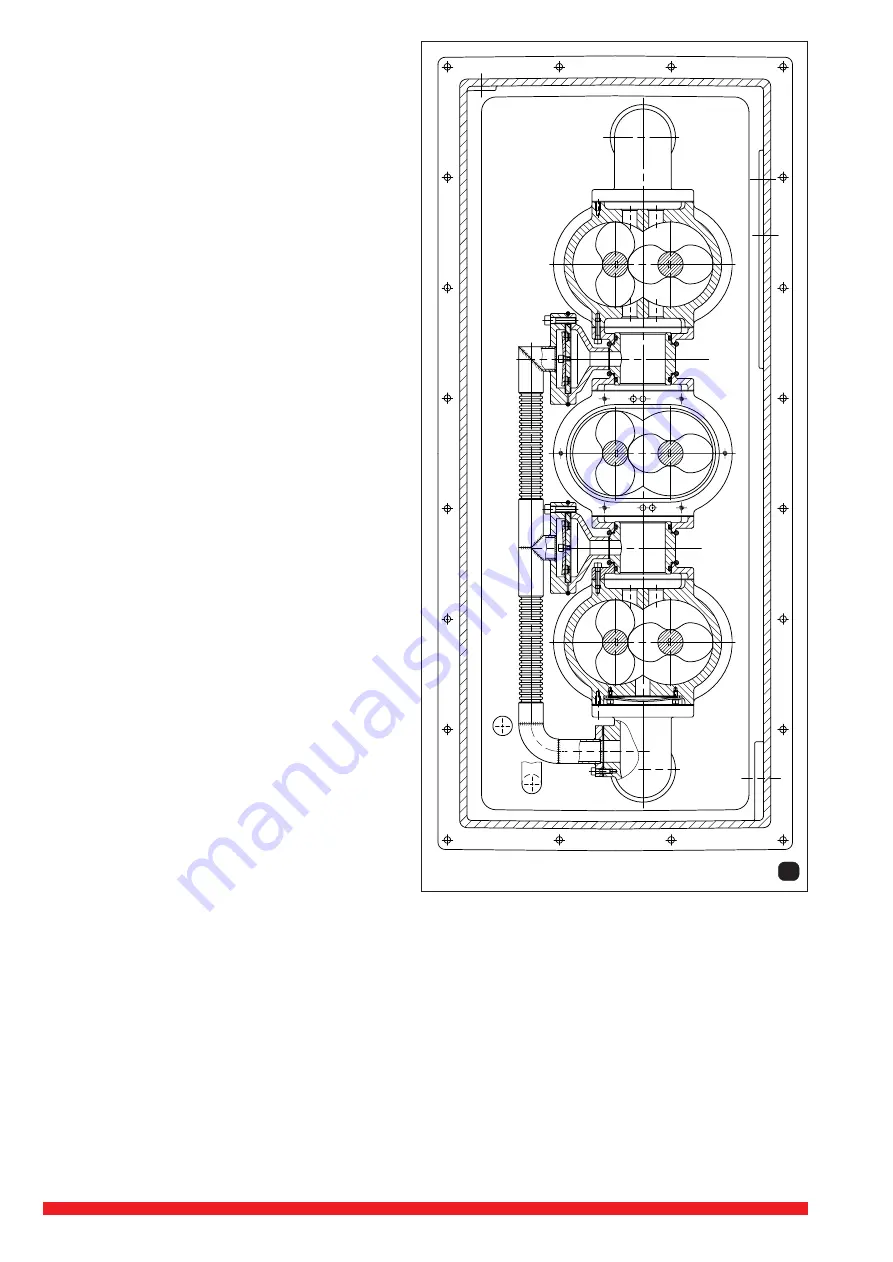

3.4.5 By-pass system (pict. 8)

The by-pass system connects the interstage LP/MP chamber

and the interstage MP/HP chamber with the exhaust duct.

The by-pass system enables the INOVAC vacuum pump to

operate at any suction pressure without overheating which

would result from the over pressure of the MP and HP stages.

The by-pass valves close when the interstage pressures are

lower than the exhaust pressure.

3.4.6 Sealing gas

The INOVAC is supplied as standard with the facility to

pressurise the shaft sealing ring chamber with an inert sealing

gas. This prevents ingress of process material through the

labyrinth piston rings, which could otherwise build up on the

shaft leading to premature wear and damage to sealing rings.

Two thread connections (S

➝

D 221) are provided on the

INOVAC for inlet and outlet of sealing gas which is fed to the

stages via a distribution block and connecting lines. The feed

to the stages is through the drive end flange. The non-drive

end is fed via lines on the left side of the stage (seen from the

drive end).

There occur two kinds of sealing gas operation.

1. Pressurising with sealing gas

The sealing gas system can be pressurised by admitting

gas to the top sealing gas port with the bottom port closed.

The sealing gas then escapes past the labyrinth and piston

ring seals into the compressor chamber, so preventing

process deposits on the seals.

The supply pressure should be 0.3 to 0.4 barG consump-

tion will be approximately 1Nm

3

/hr.

2. Finishing the sealing gas system

If it is thought that deposits may be present between the

sealing rings and the labyrinth. These can be flushed out

before starting the INOVAC. The sealing gas bottom port is

opened for 3-5 minutes, then re-closed. The system then

returns to the pressurised state.