Page 3

1. Introduction

To prevent contamination from possible dangerous sub-

stances contained in the process, the exhaust outlet must

always be connected to an appropriate emission control

system.

All units being returned to our works for mainte-

nance or any other reason must be free of harmful

and dangerous material. A health and safety certificate

should always be provided.

The customer has the responsibility for providing and check-

ing explosion proof safety requirements for the total site in

which vacuum pumps are used.

An appropriate agreement should be obtained from the local

licensing authorities.

2. Application

The INOVAC vacuum pumps are particularly suitable for the

handling of extremely humid gases. These pumps have a

high water vapour tolerance.

The ambient temperatures may be between 5 and

40° C. The suction temperatures should not exceed

60° C. For temperatures out of this range please contact

your supplier.

Liquid slugs and solids cannot be handled by

INOVAC.

Handling of explosive gases or vapours only on request

with our company.

For installations that are higher than 1000 m sea

level there will be a loss in capacity. For further

advice please contact your supplier.

The standard versions may not be used in hazardous areas.

Special versions with Ex-proof motors can be supplied.

All applications where an unplanned shut down of

the pump could possibly cause harm to persons or

installations, then the corresponding safety backup sys-

tems must be installed.

3. Design

The INOVAC is a 3 stage dry running and non-contact

vacuum pump of modular design. The INOVAC is available

in three sizes i.e. 160, 250 and 400 m

3

/hr.

3.1 Construction

With the design of INOVAC the main components are grouped

into four sections:

Drive motor • Power transmission • Vacuum cylinders

• Cooling

The reason for separation and the resulting advantages are:

1. Optimum ease of servicing in case of a stage failure:

• quick exchange of the pump stages without removing

the pump from site

• the vacuum and exhaust pipework need not be re-

moved

• the drive or power transmission parts need not be

touched

• no adjustment or alignment operations are neces-

sary due to the flange connection of the stages

2. Short down time can be achieved (approximately 3

hours) in the event of failure of a pumping stage.

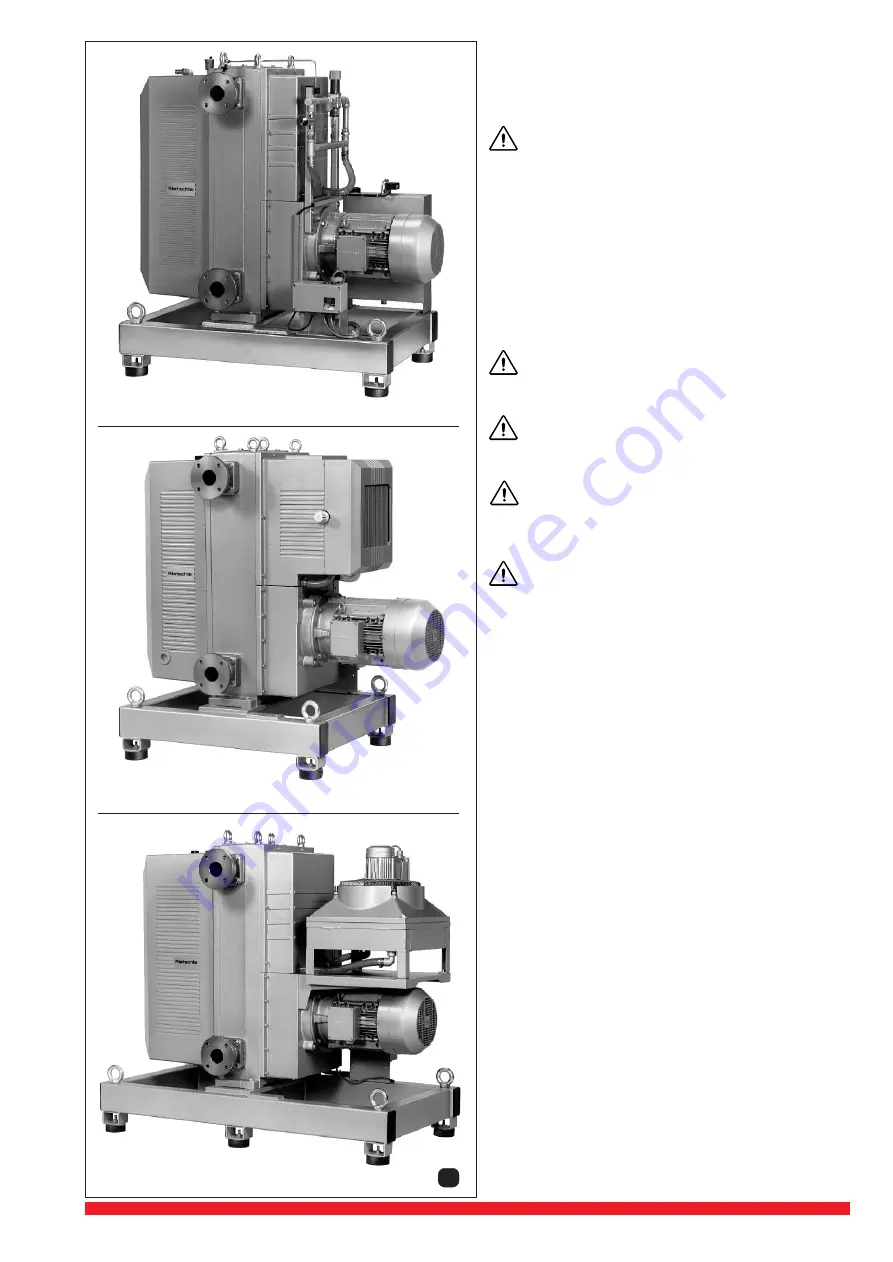

VWP 160-3 / 250-3

with external cooling

VWP 160-3 / 250-3

with closed circulation cooling

VWP 400-3

with closed circulation cooling

1