25

CHAPTER

7

Maintenance

7.3

Problems and remedies

If the burner does not work properly, first you must:

1

check that the electric connections have been correctly performed;

2

make sure that the fuel is flowing;

3

check that all the adjustment parameters (e.g. boiler water temperature or boiler steam pressure) are correctly set.

OIL WORKING

Fault

Possible cause

Recommended remedy

The burner does not start

• No electrical power supply . . . . . . . . . . . . . . . . . . . .Close all switches - Check connec-

tions

• A limiter or safety control device is open. . . . . . . . . .Adjust or replace

• Control box lock-out . . . . . . . . . . . . . . . . . . . . . . . . .Reset control box

• Control box fuses blown . . . . . . . . . . . . . . . . . . . . . .Replace

• Erroneous electrical connections . . . . . . . . . . . . . . .Check connections

• Defective control box . . . . . . . . . . . . . . . . . . . . . . . .Replace

• Air pressure switch in operating position . . . . . . . . .Adjust or replace

• Contact 2 of the servomotor, terminals 11-8 . . . . . . .Adjust cam 2 or replace the

of the control box do not operate (SQM 10) . . . . . . .servomotor (SQM 10)

• Contact 2 of the servomotor, terminals 11-8 . . . . . . .Adjust cam 2 or replace the

of the control box do not operate (SQM 40) . . . . . . .servomotor (SQM 40)

The burner does not start and a

function lock out occurs

• Flame simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . .Replace control box

The burner starts but stops at

maximum air damper setting

• Contacts 1 or 4 of the servomotor, or terminals 9-8 .Adjust cams 1 or 4 or replace the

of the control box do not operate (SQM 10) . . . . . . .servomotor (SQM 10)

• Contacts 4 or 6 of the servomotor, or terminals 9-8 .Adjust cams 4 or 6 or replace the

of the control box do not operate (SQM 40) . . . . . . .servomotor (SQM 40)

The burner ignites but then

blocks

Air pressure switch inoperative due to insufficient air pressure:

• Air pressure switch adjusted badly . . . . . . . . . . . . . .Adjust or replace

• Pressure switch pressure point pipe blocked . . . . . .Clean

is blocked

• Head wrong adjusted . . . . . . . . . . . . . . . . . . . . . . . .Adjust

The burner starts and then locks

out

• Fault in flame detection circuit . . . . . . . . . . . . . . . . .Replace control box

The burner stays in the pre-

purge stage

• Contacts 3 or 5 of the servomotor, or terminals . . . .Adjust cams 3 or 5 or replace

10-8, of the control box do not operate . . . . . . . . . . .the servomotor (SQM 10)

• Contacts 3 or 5 of the servomotor, or terminals . . . .Adjust cams 3 or 5 or replace

10-8, of the control box do not operate . . . . . . . . . . .the servomotor (SQM 40)

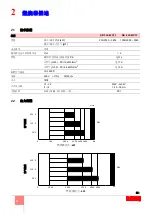

Summary of Contents for DB 4 LSM C13

Page 2: ......

Page 61: ...1...

Page 69: ...9 3 3 1 1 2 3 M12 X 25 1 2 1 2 3 3 D12015 10 7 3 4 1 1 6 5 6 2 4 3 3 20110636...

Page 71: ...11 3 3 3 12 A A 8 10mm 4 4 5mm 12 D8665...

Page 72: ...12 4 4 1 1 2 3 3 3 4 1 6 13 1 3 4 5 D8416 2 6...

Page 73: ...13 4 4 2 D7543 C GF HPG LPG MM PA PGM PGm RG SRV VE VPS VR VS 0 5 4 bar 500 mbar 14...

Page 75: ...15 5 5 2 SQM 10 1 4 2 3 5 6 7 1 2 0 20 3 20 4 5 20 130 1 4 17 D1500...

Page 78: ...18 5 5 5 19 20 21 D2213 D2215 19 20 21 D2214...

Page 79: ...19 5 5 6 EN 267 20 A B D3509 22 2...

Page 83: ...23 7 7 1 UV 70 A 187 V 100 A c c 100 F 1V c c 7 2 1 2 3 4 5 1 2 3 4 5 6 D1143 31...

Page 86: ...26 7 VR VR VS VR...

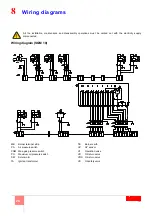

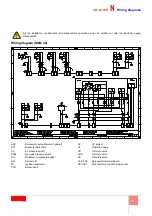

Page 87: ...27 8 SQM 10 MB PA PGM PO SM TA TB UV UV VF VR VRS VS 3 5 6 7 6 3 2 8 5...

Page 89: ......

Page 90: ......

Page 91: ......