24

CHAPTER

7

Maintenance

Safety test - with gas ball valve closed

It is fundamental to ensure the correct execution of the electrical

connections between the gas solenoid valves and the burner to

perform safely the commissioning.

For this purpose, after checking that the connections have been

carried out in accordance with the burner's electrical diagrams,

an ignition cycle with closed gas ball valve -dry test- must be

performed.

1

The manual ball gas valve must be closed

2

The electrical contacts of the burner limit switch need to be

closed

3

Ensures closed the contact of the low gas pressure switch

4

Make a trial for burner ignition

The start-up cycle must be as follows:

–

Starting the fan for pre-ventilation

–

Performing the gas valve seal control, if provided

–

Completion of pre-ventilation

–

Arrival of the ignition point

–

Power supply of the ignition transformer

–

Electrical Supply of solenoid gas valves

Since the manual gas ball valve is closed, the burner will not

light up and its control box will go to a safety lockout condition.

The actual electrical supply of the solenoid gas valves can be

verified by inserting a tester. Some valves are equipped with

light signals (or close/open position indicator) that turn on at the

same time as their power supply.

Safety components

The safety components must be replaced at the end of their life

cycle indicated in Tab. B. The specified life cycles do not refer

to the warranty terms indicated in the delivery or payment con-

ditions.

IF THE ELECTRICAL SUPPLY OF THE GAS VALVES

OCCURS AT UNEXPECTED TIMES, DO NOT OPEN

MANUAL GAS BALL VALVE, SWITCH OFF POWER

LINE; CHECK THE WIRES; CORRECT THE ERRORS

AND REPEAT THE COMPLETE TEST.

WARNING

Safety component

Life cycle

Flame control

10 years or 250,000

operation cycles

Flame sensor

10 years or 250,000

operation cycles

Gas valves (solenoid)

10 years or 250,000

operation cycles

Pressure switches

10 years or 250,000

operation cycles

Pressure adjuster

15 years

Servomotor (electronic

cam) (if present)

10 years or 250,000

operation cycles

Oil valve (solenoid)(if

present)

10 years or 250,000

operation cycles

Oil regulator (if present)

10 years or 250,000

operation cycles

Oil pipes/ couplings

(metallic) (if present)

10 years

Flexible hoses (if present)

5 years or 30,000 pressurised

cycles

Fan impeller

10 years or 500,000 start-ups

Summary of Contents for DB 4 LSM C13

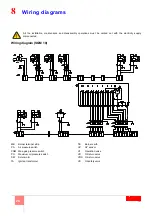

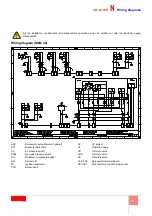

Page 2: ......

Page 61: ...1...

Page 69: ...9 3 3 1 1 2 3 M12 X 25 1 2 1 2 3 3 D12015 10 7 3 4 1 1 6 5 6 2 4 3 3 20110636...

Page 71: ...11 3 3 3 12 A A 8 10mm 4 4 5mm 12 D8665...

Page 72: ...12 4 4 1 1 2 3 3 3 4 1 6 13 1 3 4 5 D8416 2 6...

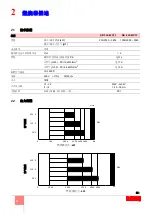

Page 73: ...13 4 4 2 D7543 C GF HPG LPG MM PA PGM PGm RG SRV VE VPS VR VS 0 5 4 bar 500 mbar 14...

Page 75: ...15 5 5 2 SQM 10 1 4 2 3 5 6 7 1 2 0 20 3 20 4 5 20 130 1 4 17 D1500...

Page 78: ...18 5 5 5 19 20 21 D2213 D2215 19 20 21 D2214...

Page 79: ...19 5 5 6 EN 267 20 A B D3509 22 2...

Page 83: ...23 7 7 1 UV 70 A 187 V 100 A c c 100 F 1V c c 7 2 1 2 3 4 5 1 2 3 4 5 6 D1143 31...

Page 86: ...26 7 VR VR VS VR...

Page 87: ...27 8 SQM 10 MB PA PGM PO SM TA TB UV UV VF VR VRS VS 3 5 6 7 6 3 2 8 5...

Page 89: ......

Page 90: ......

Page 91: ......