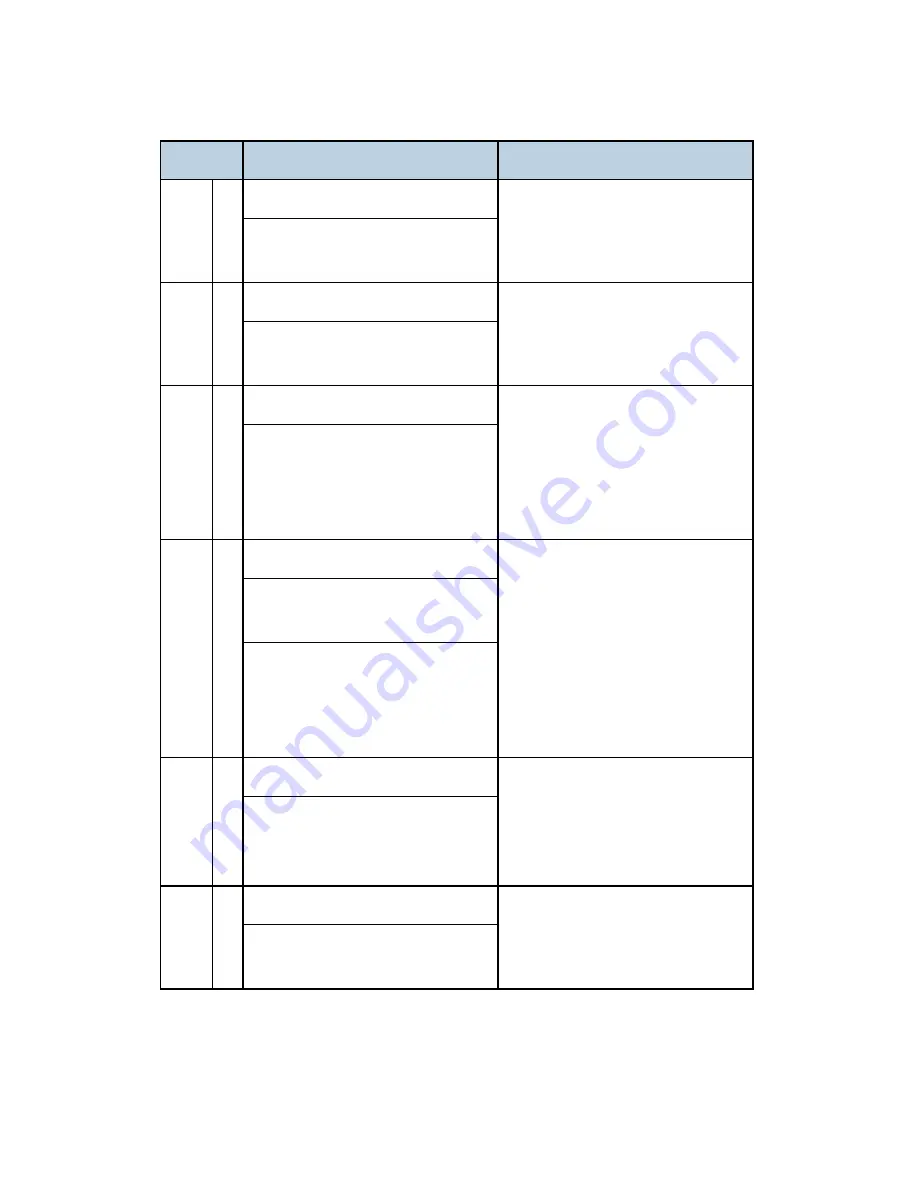

Service Call Conditions

M047 2-4

SM

Appendix

Code No.

Symptom

Possible Cause

530 B

Fusing fan error

Poor connection of the fusing fan

Fusing fan defective

The CPU detects the fusing fan lock

signal for more than 3 seconds.

531 B

PSU fan error

Poor connection of the PSU fan

PSU fan defective

The CPU detects the PSU fan lock

signal for more than 3 seconds.

541 A

Thermistor error

Thermistor

defective

The fusing temperature detected by

the thermistor is 0

°

C for 7 seconds

after the fusing relay has been turned

on.

542 A

Fusing temperature warm-up error

Thermistor defective or

deformed

Fusing lamp open

Fusing thermostat open

The fusing temperature does not

increase by 7

°

C for 10 seconds.

The fusing temperature does not

reach more than 135

°

C for 24

seconds after the main switch is

turned on.

543 A

Fusing overheat error: Software

Fusing thermistor defective

Power supply board defective

A fusing temperature of over 235

°

C

is detected for 0.5 seconds by the

fusing thermistor.

544 A

Fusing overheat error: Software

Fusing control out of control

Power supply board defective

The machine detects an overheat

error of the hardware.

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Summary of Contents for SP 6330N

Page 1: ...M047 SERVICE MANUAL 005630MIU C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 2: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 3: ...M047 SERVICE MANUAL C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 4: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 5: ...M047 SERVICE MANUAL 00M047MIU C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 6: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 8: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 10: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 12: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 18: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 20: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 26: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 32: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 34: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 40: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 42: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 46: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 48: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 102: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 104: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 116: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 122: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 124: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 132: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 133: ...M047 SERVICE MANUAL APPENDICES C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 134: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 136: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 138: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 148: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 162: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 264: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 266: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 268: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 270: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 276: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...

Page 278: ...C PIA N O CONTROLADA C PIA N O CONTROLADA...