4

5

PRE-INSTALLATION ASSEMBLY REQUIREMENTS

BEFORE INSTALLATION, ENSURE THAT YOUR DOOR IS PROPERLY BALANCED AND RUNNING

SMOOTHLY. ALSO ENSURE THAT THE LIMIT BRACKETS (SUPPLIED) ARE INSTALLED AND

SECURED PROPERLY. BUMPER/PUSHER SPRINGS MAY BE USED IN PLACE OF, OR IN ADDITION TO

LIMIT BRACKETS FOR DYNA-HOIST OPERATORS, BUT MUST BE INSTALLED PRIOR TO OPERATION.

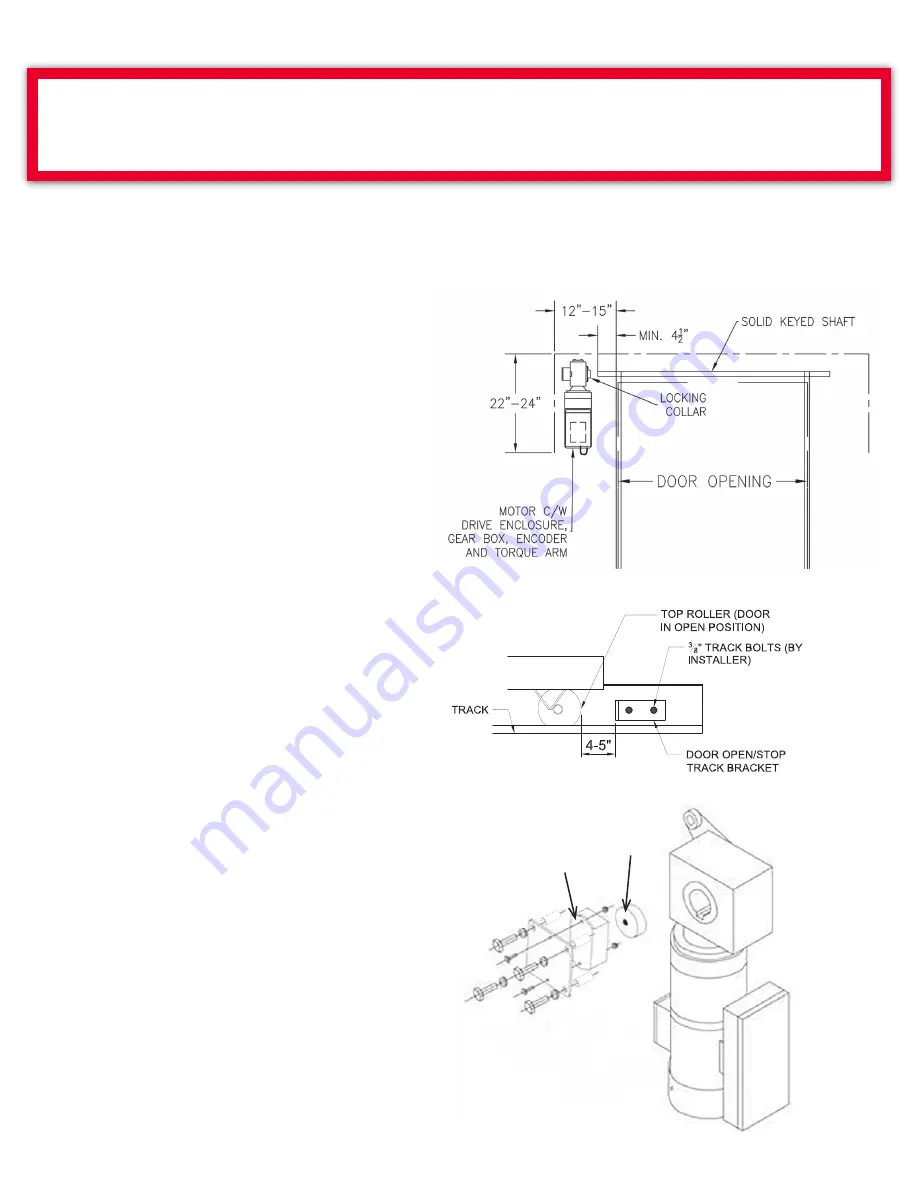

Operator Mounting Requirements

Dyna-Hoist operators are mounted directly on the door shaft. Before installing the operator, please ensure follow-

ing criteria is met:

The door is well balanced, is tested for smooth

functioning without any unusual noise.

Provided Limit Brackets must be installed

4"-5" past door's desired open position (and within

allowable maximum cable height) to prevent the

doors from over-travel. (See Fig. 1A)

The door has a solid keyed shaft with a minimum

exposed length of 4.5” on the operator side.

Clearance of at least 12” horizontally from the

side of the door (or 9” from end of shaft), and

24” vertically below the shaft. There is adequate

structural support surface to securely install the

torque arm mounting bracket, the torque arm and

the junction box. For more details, see mounting

installation instructions

Fig: 1 & 7.

Mounting space for the operator Control Panel

(Min. 5 ft. from ground level, within clear sight of the

door but far enough away as to prevent users from

contacting moving parts).

Left Hand Mounting:

The factory default mounting as shown

(Shown in Fig: 2) is for left-hand side of the

door, hence no modification is required.

FIGURE: 1

FIGURE: 2

Magnet on

this side

Encoder

FIGURE: 1A

Summary of Contents for DYNA-HOIST DC Series

Page 7: ...7 TORQUE ARM POSITION IN RELATION TO OPERATOR ...

Page 13: ...13 WIRING DIAGRAMS ...

Page 14: ...14 ...

Page 15: ...15 ...

Page 16: ...16 ...

Page 17: ...17 ...

Page 26: ...26 DYNA HOIST OPERATOR COMPONENTS ...

Page 31: ...31 NOTES ...